StoneCycling's co-founder Ward Massa on transforming waste, using common sense and future-proofing.

Ward Massa & Tom van Soest

StoneCycling was set-up in 2009 at the Design Academy Eindhoven in the Netherlands, where, as a student, Tom van Soest focused on upcycling waste he found in vacant buildings awaiting demolition. Tom began grinding, crushing, and mixing this waste in his homemade industrial blender; after "many, many trials—and even more errors"—he found a way to create new materials that were both resilient and appealing.

After graduating, Tom started StoneCycling with his long-time friend Ward Massa, and in 2015 they unveiled their first series of WasteBasedBricks. The following year, the first ever building made from the bricks was constructed in the heart of Rotterdam. Upcycling fifteen tonnes of waste into a brand-new façade was both a major milestone and a glimpse of things to come. Since then, the duo's business has gone from strength-to-strength.

We caught up with co-founder Ward to talk process, projects to date and what's on the horizon. Here's what he had to say...

How would you describe WasteBasedBrick?

"The WasteBasedBrick® is a sustainable building material with high technical and aesthetic value that is being used for the facades of buildings and interior wall cladding."

What is your making process?

"Debris from construction and demolition is one of the biggest waste streams in the world. In Europe, it accounts for approximately 30% of all waste generated. In countries like the United States and China, this percentage is even higher.

"At StoneCycling, we’re doing continuous research on the availability, quality and quantity of waste that has the potential to be upcycled. In many cases, we do this together with our waste partners, and in some instances this means that we need to improve the quality of the waste.

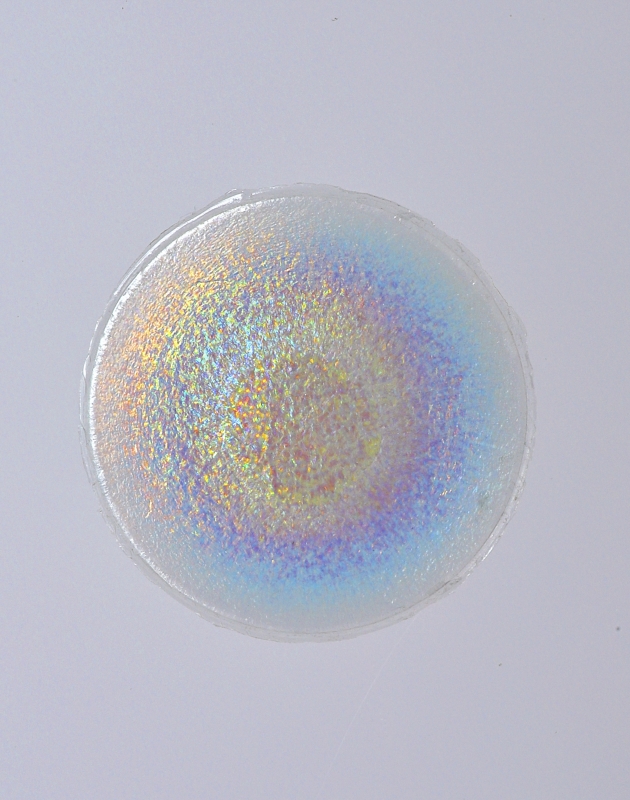

"One of our missions is to prove that waste can be beautiful. Throughout the production process, this means we’re relying on true (and old fashioned) craftsmanship.

"Yes, everything can be done by robots today. But we value the experience of the men and women that have been doing this work for years. We believe it puts heart into our products. It also means that we can make everything and anything (but standard products)."

Where do you source your waste?

"Mainly in The Netherlands. We try to source as local as possible to limit transportation movements."

Typically, who specifies your material?

"Architects, interior designers and design teams of large fashion and retail chains. Mostly people that want to create something beautiful and something sustainable. They are typically the early adaptors in the market."

And is there a specific type of project you regularly see it featured in?

"Yes, iconic buildings in the capitals around the world. Retail chains, private houses with a focus on sustainable architecture."

Do you plan on rolling out your making process to other materials/products?

"Yes, we are currently working on expanding our product range of tiles and flooring with new technologies."

Photography: Milosz Siebert

Photography: Milosz Siebert

Are you influenced by trends?

"I would say by common sense. We need to completely rethink how we make our products, build our buildings and deal with our waste."

Is there a particular project that's used your material that you're most fond of?

"I like this one. It gives an idea of the power of waste."

Are there any other manufacturers/designers that particularly inspire you/your team?

"Yes, Tony's Chocolonely. Different product but we love their vision. It basically says 'hey, we’re here now but need to move there. Let's do our best to get there in fastest way possible.'"

What are you currently working on?

"Exciting projects in New York, London, and this one in Amsterdam."

And what's coming up next?

"Many things. Follow our work on Instagram."