Breaking free from foam: Modus in conversation with Pearson Lloyd.

If you've visited Material Source Studio Manchester in the last fortnight, you'll have been acquainted with our latest furniture Partner, Modus.

With the tagline, 'Thoughtfully made British furniture', for over two decades, the company has been manufacturing the aforementioned, bringing together British craftsmanship, sustainable innovation, and workplace functionality.

Taking a life cycle thinking approach to product development, Modus applies material intelligence and design understanding to all the pieces in its collection, helping to develop low impact furniture for a better future.

With this in mind, Modus illustrates a clear desire to do things differently. Highlighted beautifully through an ongoing collaboration with London-based design agency, Pearson Lloyd, leading to a departure away from using plastic foam.

In the conversation to follow, Modus and Pearson Lloyd discuss their dual creative approach to crafting a market differentiator.

“The interaction between people, product and place – and how a product or system can affect our behaviour – lies at the heart of our practice.” It is this mantra that sits as a core principle of Pearson Lloyd’s approach and one that was applied to the development of Pearson Lloyd Edge for Modus, a comprehensive and flexible workplace furniture system that was launched in 2015.

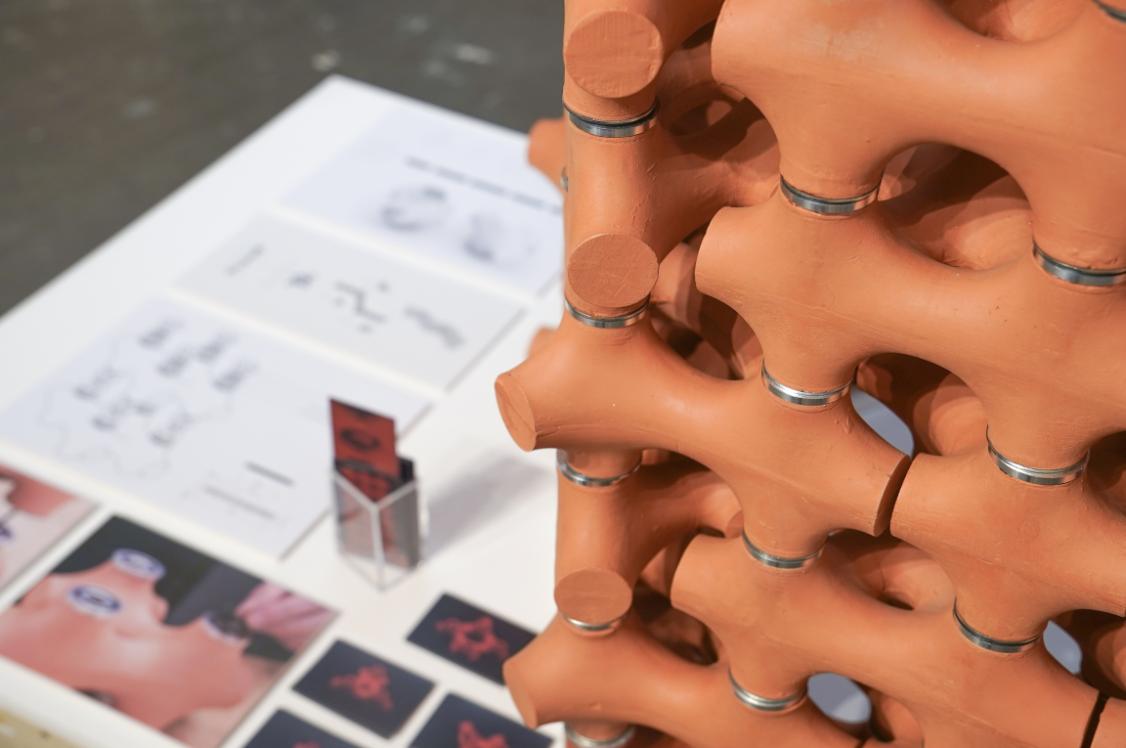

“It all started with a knuckle,” says Luke Pearson with a chuckle. “Or more precisely, a corner knuckle.” This knuckle is in fact the cast aluminium piece that forms the corner joints of the system – the meeting point for the extruded horizontal supports of each product and the sturdy legs. The design is underpinned by these carefully engineered structural components but is nevertheless imbued with a visual simplicity. The strength of the knuckle gives the system the potential for multiple products, always carried off with a coherent visual identity.

In 2023, the Pearson Lloyd Edge system expanded to include the first foam free seating, Edge Free for Modus. Tom Lloyd and Luke Pearson share what it takes to bring a low carbon, foam free product to life.

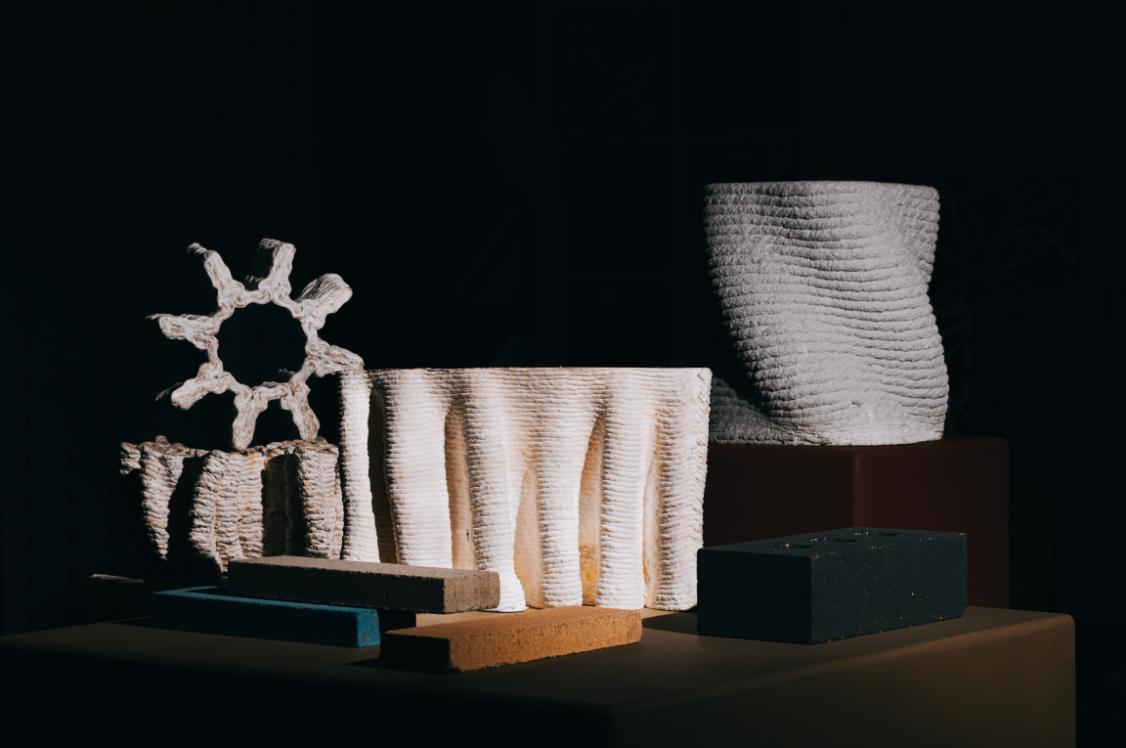

“The idea of shifting from traditional polyurethane (PU) foam to natural fibre alternatives came from their commitment to reducing the environmental impact of their products. While commonly used for its comfort and resilience, PU foam is derived from petrochemicals. They wanted to explore materials that were renewable, biodegradable, and had a lower carbon footprint during production and disposal. Natural fibres, like coconut coir, offered a compelling alternative due to their availability as waste materials, their durability, and minimal environmental impact. This aligns with the studio’s broader sustainability goals, aiming to design with a circular economy in mind—prioritising recyclable or biodegradable materials and reducing reliance on finite resources.

"Although coconuts grow in tropical regions far from most manufacturing locations, coconut fibre, or coir, is a byproduct of the food industry. Unlike PU foam, which involves energy-intensive processes with significant greenhouse gas emissions, coconut coir is a natural waste material that would otherwise go unused. Coir is biodegradable, whereas PU foam usually ends up in landfill where it can persist for centuries. The environmental footprint of transporting coconut fibre is far outweighed by the reduced impact associated with its production and end-of-life disposal. Using coconut fibre also supports local economies in low-middle income countries.

"It is likely that the UN treaty to end plastic pollution will eventually impact the manufacture of furniture. As global awareness of the environmental and health impacts of plastic pollution grows, regulations aimed at reducing or eliminating the use of harmful plastics will become more stringent. The future role of plastic in furniture will shift towards more sustainable and circular applications. While the use of virgin plastic may decline due to environmental concerns and regulatory pressures, recycled and bio-based plastics will become more prevalent. Plastics may still be used where their properties—such as durability, flexibility, and lightweight nature—are essential, but with an emphasis on designs that facilitate recycling and reuse.

"The furniture industry, like others, will need to adapt by finding alternatives to traditional plastic materials, increasing the use of recycled or bio-based content, and designing for easier disassembly and recycling, both of which the designers are starting to see.

"Manufacturers will also need to adopt more transparent practices, ensuring that their materials and processes align with emerging regulations and consumer expectations for sustainability. This shift could drive innovation in materials science, encouraging the development of new, sustainable materials that can replace plastics while maintaining the functionality, durability, and aesthetics required for high-quality furniture.”

Discover more about Modus here, and experience its products in situ at Material Source Studio Manchester. Plan your visit.

In association with

For over two decades, we have been manufacturing thoughtfully designed furniture that brings together British craftsmanship, sustainable innovation, and workplace functionality.