Carbon-12: EcoCocon, straw panel construction.

Image credit: Tim Ainsworth

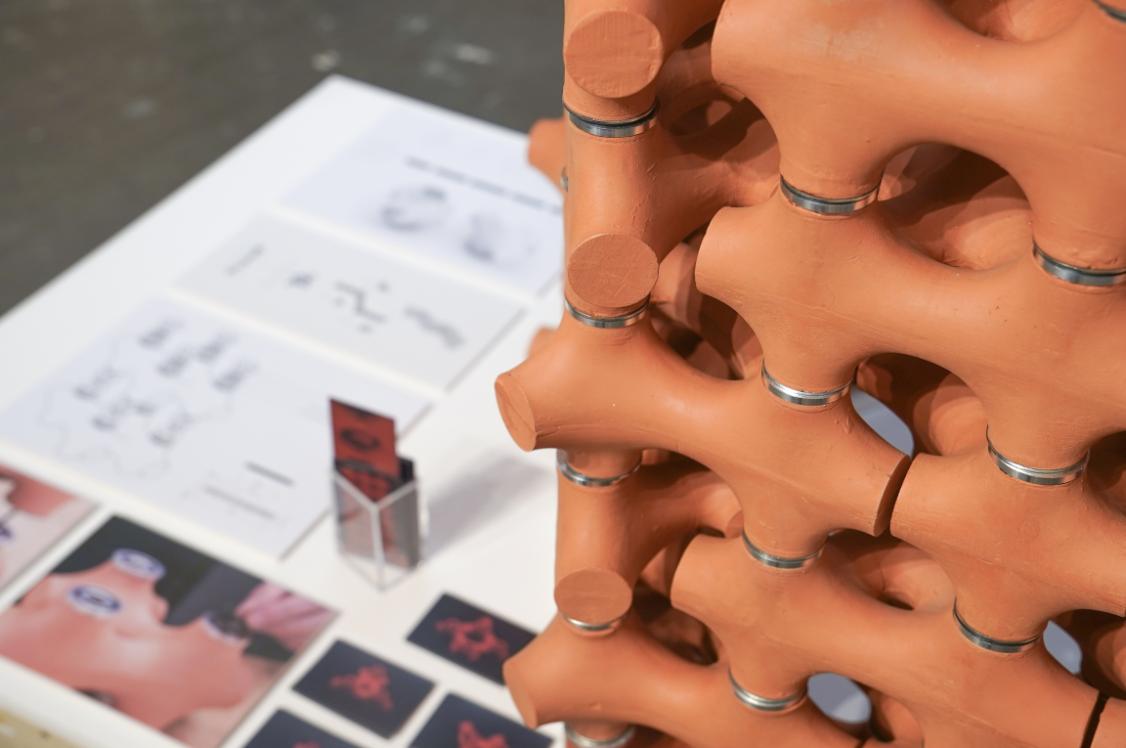

EcoCocon fabricates straw wall panels for construction, made on average of 89% straw, and 10% timber.

Utilising natural materials, its panel system can be used for both exterior and interior application.

Carbon credentials

- Manufacturer: EcoCocon

- Product: EcoCocon Panel

- Material: 89% straw, 10% timber

- Applications: Straw panel construction system

- Carbon status: Carbon sequestering

- Accrediting body: MRPI

- EPD: Yes / No / Pending

- Additional credentials: Cradle to Cradle Silver Certification Passivhaus Certificate, FSC Certificate, PH Certification Report, Passive House Institute, Certificate of Conformity CE Timber

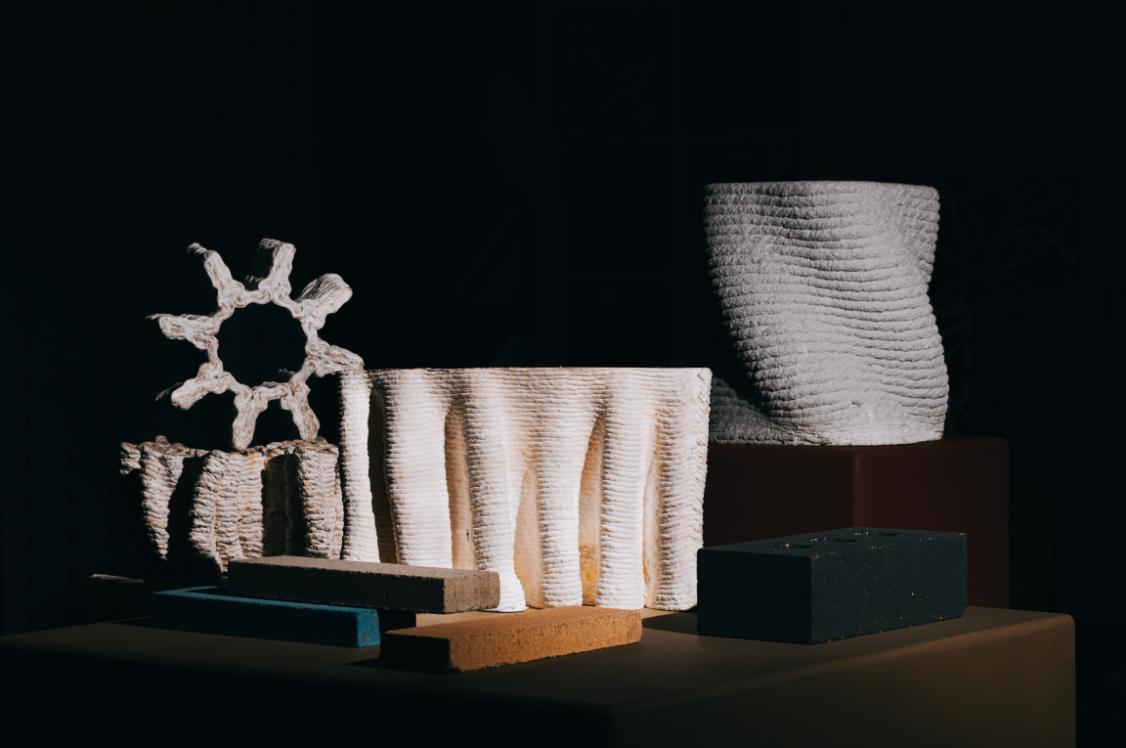

Straw as a material has a centuries long history in architecture; used for roofing, insulation and constructing walls. An indigenous and relatively cheap building material, it has in recent years experienced a resurgence as an ecological alternative to synthetic construction materials.

Image credit: Tim Ainsworth

Image credit: Tim Ainsworth

EcoCocon's straw-based construction system is designed to use as little wood as possible – just enough for it to be load-bearing. The FSC Certified timber is sourced from Sandasa Timber AB, Sweden, and the straw is sourced from local farms nearby the manufacturing facilities in both Lithuania and Slovakia - a byproduct of agriculture wheat production. Used in their raw states, the production process demands very little primary energy.

Both materials sequester large amounts of CO₂ through photosynthesis over their lifetime. This CO₂ is then safely stored in the construction, resulting in a highly positive climate impact. Panels in a typical house with an external wall area of 130 m2 sequester more than 12 tonnes of CO₂e.

EcoCocon’s straw wall system is prefabricated under project-specific specification in its factory in Slovakia under rigorously controlled conditions. SketchUp and CAD / BIM software are used for coordinating architectural and structural information with its clients.

EcoCocon Factory, Slovakia.

EcoCocon Factory, Slovakia.

While the system is predominantly designed to be used in external walls, it can be utilised internally. EcoCocon strongly encourages the use of clay plaster as an interior finish as it acts as an effective humidity regulator. It absorbs excess humidity and releases it when the humidity levels drop. The entire straw panel system is permeable to vapour – it allows excess humidity to escape. It leaves no space for mold because it’s fabricated to be airtight with no thermal bridges.

It’s a product used to achieve Passivhaus certification and carries a Cradle to Cradle Silver certification.

Its EPD is externally verified by MRPI®, with the LCA study conducted by Zoë Tan, Hedgehog Company BV. This study focuses on an average wall panel from an EcoCocon construction, which typically consists of six types of EcoCocon panel, 40cm deep. The exact dimensions of the EcoCocon panels vary.

EcoCocon Factory, Slovakia.

School of Life, Denmark. Image credit: Sophia Lydolph

School of Life, Denmark. Image credit: Sophia Lydolph

EcoCocon panels have excellent sound insulating properties - resistance to the passage of sound of 54 dB. This results in exceptional acoustic comfort.

Straw has a high content of silica, a natural fire retardant. The straw in its panels is compressed at a density of 115 kg/m³, leaving no space for oxygen that would fuel the fire. When burning, both materials create a charcoal insulation layer on the surface that protects them from flames. Combined with clay plaster, the panels can withstand two hours of intense fire according to the REI 120 and REIef120 certifications, meeting strict fire safety requirements.

EcoCocon panels have been specified at a number of different scale projects, from apartment blocks and educational facilities to industrial buildings. It’s a company that is redefining what low-carbon prefabrication can be, and is a zero waste manufacturing operation.

Danish project, Feldballe Friskole utilised EcoCocon panels in its specification. The project was focused on testing five sustainable design principles formulated by Henning Larsen Architects: bio-based materials in construction that sequester carbon, design for disassembly, good indoor climate, good daylight levels and natural ventilation, free of toxic chemicals, and reuse of local materials.

School of Life, Denmark. Image credit: Sophia Lydolph

Designed by Baxter Projects, a 1000m2 Zen Buddhist straw temple in the Hudson Valley, New York, specified EcoCocon in its construction. The off-grid sanctuary is made largely from bio-based materials. One of the buildings is an accommodation block with 6 single bedrooms, 4 bedrooms with a living space and a large kitchen. The second building is a community building with a meditation hall, art studio and a library with more than 7000 books.

A 12-storey building with 65 apartments in Malmö, Sweden, is responsibly constructed with CLT, with EcoCocon panels forming the external envelope. There are 10 storeys of accommodation above ground floor, café and retail, and the top floor is used for storage and plant space. The building has been designed to a Passivhaus standard, with extremely low energy consumption to achieve low energy bills and long-term comfort. Construction commenced in 2024 and the completion is scheduled for 2025.

Discover more about EcoCocon at our Carbon-12 installation across both Manchester & Glasgow Studios. No booking required.