Carbon-12: Forbo, Marmoleum.

Image credit: Tim Ainsworth

Marmoleum is Forbo Flooring Systems’ popular linoleum flooring solution.

Containing up to 98% natural raw materials and 43% recycled content, this product is independently certified as climate positive (carbon negative) from cradle to gate, without offsetting.

This flooring and furniture surface solution removes 663 grams of carbon dioxide from the atmosphere for every square metre produced. Available in +300 colourways and 12 different product types, Marmoleum is used across a variety of sectors including healthcare, education, retail, workplace and private rental sectors.

Carbon credentials

- Manufacturer: Forbo Flooring Systems

- Product: Marmoleum

- Material: +97% natural materials: Linseed oil, wood flour, jute, limestone, pine rosin

- Applications: Flooring

- Carbon status: Climate Positive (carbon negative) – without offsetting

- Accrediting body: UL

- Additional credentials: BREEAM, LEED, Red List Free, USDA Certified Biobased Product, hpdc membership, Allergy UK Seal of Approval, Nordic Swan, Blue Angel, Indoor air comfort GOLD

- EPD: Yes / No / Pending

Marmoleum 2.0 - 2.5mm EPD Marmoleum 2.5mm EPD Furniture Linoleum EPD Marmoleum Decibel EPD Marmoleum Modular Slate & Walton EPD Marmoleum Modular Striato & Textura EPD Marmoleum Modular Piano - MCT EPD

Environmental Transparency Passport Marmoleum 2.0, 2.5, 3.2mm sheet

Forbo also offers its Marmoleum Cocoa range, incorporating waste from the chocolate industry into its typical production processes.

Forbo Flooring Systems’ core sustainability principles are renewability, transparency and circularity, with the environmental benefits of its products considered at every stage of their life cycle. To this end, the manufacturer continues to innovate its production processes and increase the bio-based content of its product portfolio. Since 2004, Forbo has decreased its average carbon emissions per m2 by 81%, without offsetting. It produces an annual sustainability report, the most recent being its Sustainability Report 2024.

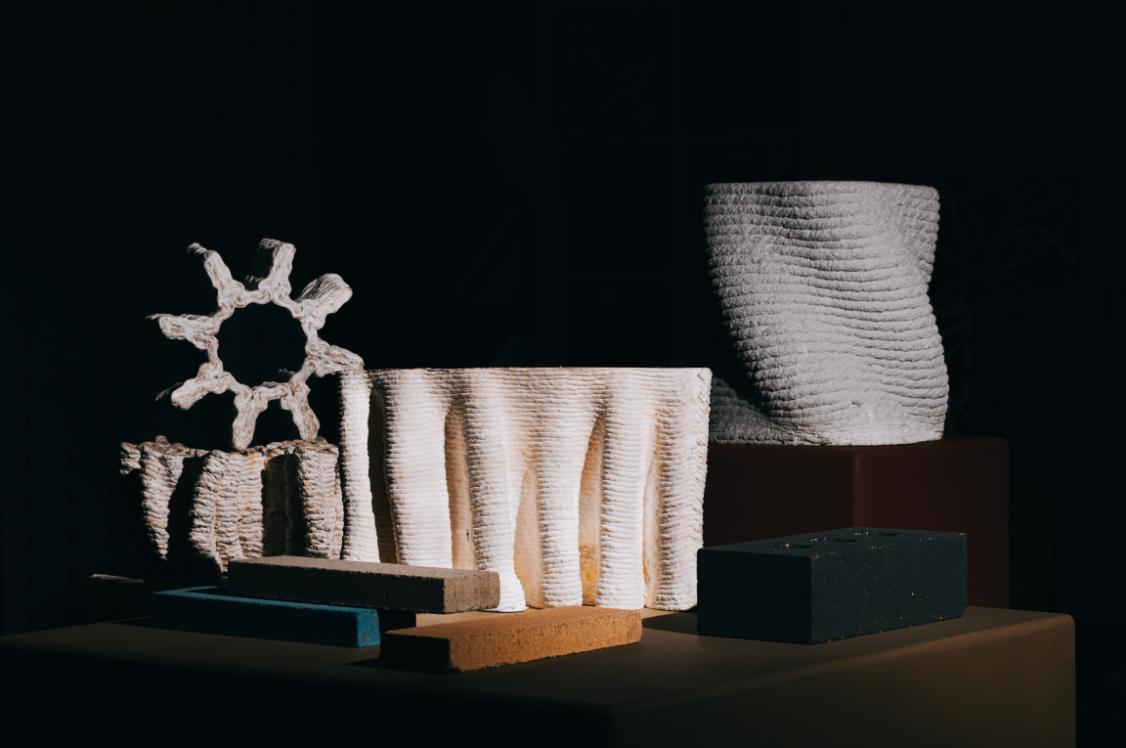

Image credit: Tim Ainsworth

Image credit: Tim Ainsworth

For every square metre of Marmoleum produced, 663 grams of carbon dioxide is removed from the environment. This is due to the raw materials used to create the product, of which 70% are rapidly renewable, with linseed oil, jute, pine rosin, wood flour and limestone making up the majority of Marmoleum production.

In addition to this, Marmoleum contains 43% recycled content, with 33% of this made up of industry and installation waste, as well as End of Life (EOL) recycled Marmoleum waste. Finally, organic pigments and iron oxide are used to provide the colouring for the linoleum granules, creating beautiful natural designs.

Marmoleum is independently verified as being Climate Positive (carbon negative), without offsetting. This means that the CO₂ removed from the atmosphere during the growth of its natural ingredients exceeds the CO₂ produced in the extraction, transportation and manufacturing processes. Contributing to healthier indoor environments, Marmoleum has the Indoor Air Comfort Gold standard. Embodied Carbon Overview - May 2025.

The product has a range of other accreditations, including the Nordic Environmental Label, Indoor Air Comfort Gold, is Red List Free and is a USDA certified 100% biobased product. It is used to meet building rating schemes like LEED, BREEAM and the Well building standard.

In the production of Marmoleum, firstly linseed oil and pine rosin are added to large boilers and combined to create linoleum cement through an oxidation process. This linoleum cement is then stored in a heated storage room for between 10 and 14 days, until it reaches the right consistency and elasticity.

After this, wood flour is added to create a firm, dry mixture. Finely ground limestone is mixed in along with colour pigments to create a firm homogenous mass, with this mixture then shredded in various stages as it is transported to storage lofts in preparation for the final stage.

The linoleum granules are transported to the final mixing process where they are cut into one-metre-wide sheets, before being cut into two-metre-wide slabs using a rotating blade. These slabs are flipped over ready to be combined with the jute material, which is the backing for the finished flooring solution.

The jute and the linoleum slabs then meet in front of a large calendar, with two cylinders of a different temperature and speed pressing the two layers together to the correct thickness. The sheet is transported to a drying chamber, where it remains for 14 to 20 days before receiving its final finish. Topshield Pro, a specially developed finish, is applied in two layers, a primer and a finishing layer, both of which are UV cured, providing the sheet with durable protection.

As a material, Marmoleum is naturally bacteriostatic and has been independently proven to inhibit the growth and spread of infections such as Norovirus, MRSA, Acinetobacter baumannii and C Difficile. This knowledge makes the flooring far easier to clean and maintain, with less reliance being placed on harsh cleaning chemicals.

Within Hammersmith Hospital, Marmoleum was specified for its natural palette of colours, wayfinding purposes, its sustainability benefits and the durability it provides. Denise Cloutt, project architect from Ansell and Bailey, puts forward: “Forbo’s Marmoleum flooring was perfect for this project as it is an inherently natural product, manufactured from up to 98% natural raw materials and 43% recycled content. It worked well in conjunction with the wider imagery we utilised to bring nature into the space, and we really liked the fact that Marmoleum incorporates ecologically friendly pigments – reflecting the theme throughout the wider design scheme.

“We specified Marmoleum across a variety of the build, including in the offices, consultation and exam rooms and all of the circulation areas. This was in the Rocky Ice, Bluemoon, Leaf, Sage, Blue Heaven, Moonstone, Orbit and Calico colourways from across the Striato, Fresco, Concrete and Splash ranges.”

Within 16-18 Potterrow, Rebecca Finney, creative director at Jasper Sanders + Partners, comments on Marmoleum’s alignment with the project’s sustainability benefits and the product’s key design functions: “In the entrance arrival area, we specified Marmoleum Real in the Dark Bistre colourway, a rich, marbled coffee shade with undertones of ochre echoing the notion of Scottish whisky. This created a sense of drama upon entry into the building. We also used Marmoleum Concrete within the studios, not only providing durability but a neutral base too.

"While design excellence is a core value for us, we are equally committed to creating spaces that are thoughtfully crafted for both functional purpose and environmental responsibility. With Marmoleum one of the most sustainable floor coverings on the market, and certified Climate Positive (carbon negative) from cradle to gate without offsetting, these objectives were met.”

Forbo has begun working with the Salvation Army’s Trading company, SATCoL with donations of surplus carpet tiles, lifted from corporate refurbishment and renovation projects. As part of the charity’s Take Back Scheme, the carpet tiles will be distributed to the charity’s furniture shops around the UK, providing communities with easy access to affordable and high-quality flooring. The initiative provides a second life to carpet tiles that may otherwise be sent to landfill, despite having many more years of use in them.

In addition to this, Forbo operates its ‘Back to the Floor’ scheme, which reprocesses installation off-cuts and unwanted samples of a variety of its floor coverings.

Discover more about Forbo's Marmoleum collection at Material Source Studio Manchester & Glasgow as part of Carbon-12.