Future Materials Library™ launches at Material Source Studio.

Credit: Tim Ainsworth

Future Materials Library™ is the UK's most extensive open collection of regenerative materials for built environment use.

The materials featured have been sourced from around the world, over a span of seven-years, in what will be a continually evolving roster. And it's now ready to be explored at Material Source Studio.

"When we first started talking about future materials, it very much felt like we were championing materiality for exactly that, the future. Something distant. Science fiction. A time that was still yet to come.

Fast-forward almost seven-years, and the concept of biomaterials is commonplace. That future that we gazed into is, in theory, now here. But for the most part, we are still talking in theoretical terms. When bio-based, recyclable, low carbon, or regenerative design is used on a scheme, it’s best practice. An award winner.

For that reason, the future we had dreamt of back in 2019 isn’t quite here yet. We’re on the precipice. Innovation is rife. But without investment from the sector, business-as-usual is still the norm.

While the trail-blazing designers we provided a platform for all those years ago have become more established, moving from kitchen tables to labs to expand their experimentation, the opportunity for development in regenerative solutions for use in the built environment is vast.

What’s needed from all of us goes beyond interest to supportive investment. And that’s why, alongside our world-class Partners with ready-to-specify products, we’ve launched the Future Materials Library™ - to be featured in every Material Source Studio location: Manchester, Glasgow, and London - comprising the UK’s largest open collection of regenerative materials for built environment use.

Curated by Emily Bagshaw, creative at Material Source Studio, and drawing from editorial content by Laura Connelly, editor-in-chief, researched and written from 2019 onwards - both whom are passionate champions of design innovators, the in Studio selection features over 100 materials for architects and designers to explore for use in their schemes on permanent display.

The designers and brands featured date back to our very first exhibition, ‘From the Ground Up’ at Material Source Studio Manchester in 2022, which global practice Gensler loaned as inspiration for its European team, to ‘This Is No Longer Speculative’ in 2024, receiving thousands of visitors in both Manchester and Glasgow, and to ‘Carbon-12’ our latest installation on the carbon journeys of materials for 2025.

Our aim has always been to support those pushing forward products and materials for a more sustainably sound future. And as we said at the top – that ‘future’ we believe can be here.

Along with our Studio Partners, who have insisted that alongside their ready-to-specify products we provide a showcase for future innovation, they too believing in true sustainability, we’re proud to be offering what we believe is a crucial, ever-evolving resource for you, the built environment sector - for free and open to visit all year round.

Displayed on a next generation POD system designed in collaboration with Tim Denton back in 2019 – a third iteration of the one we launched during the Manchester Studio's inception – the materials are brought to life for exploration, with a key and coinciding QR codes for quick access to more information should you need it.

Many thanks, as always, for your support – Material Source Studio wouldn’t be what it is without you. And we hope you find this new resource inspiring and useful in equal measure."

Darren Clanford & Michael Rogan - Co-founders, Material Source Studio

Future Materials Library™ is now open at Material Source Studio London, Manchester and Glasgow. Discover the launch exhibitors below.

Ignorance Is Bliss. Image credit: Agne Kucerenkaite

Agne Kucerenkaite - Ignorance Is Bliss

Ignorance Is Bliss ceramic tiles are glazed using pigments derived from industrial metal waste and by-products, avoiding the need for mining and excessive processing. With up to 50% waste content, the glazes source materials from industries like drinking water supply and soil remediation, which generate thousands of tonnes of residue annually.

The collection features over 20 carefully curated colours, the result of years of extensive research. Tiles are handmade, leading to subtle variations in shades. Free of lead and barium, the tiles are designed with environmental responsibility and are evolving towards full circularity by implementing materials like biofuel waste.

AgoFoam, AgoFoam T, AgoRock. Image credit: Agoprene®

Agoprene® - AgoFoam, AgoFoam T, AgoRock

Agoprene is a foam made from seaweed, offering a sustainable alternative to petroleum-based polyurethane. It’s renewable, biodegradable, and naturally fire-resistant (no need for flame retardants).

With proven durability for over 10 years and a semi-closed-cell structure that provides comfort and support, it’s built to handle everyday use. Agoprene also breaks down naturally in soil, helping to lower CO₂ emissions and reduce reliance on fossil fuels.

Developed with the furniture industry, it’s a practical material for creating more sustainable products - without overcomplicating it.

WHEATEX®. Image credit: My Linh Nguyen

Agreka Build - WHEATEX®

Agreka Build is a UK-based materials innovation company pioneering net zero construction and regenerative building solutions.

Partnering with farmers, it transforms agricultural fibre into high-performance materials that cut emissions, support rural economies, and drive the transition to a circular, low-carbon future.

Its flagship product, WHEATEX® Thermal & Acoustic Insulation Fibreboard, is made entirely from agricultural straw and designed as a sustainable alternative to synthetic insulation. At the end of its life, it can be fully recycled or composted, closing the loop in material use.

With its high-density, non-directional fibre structure, WHEATEX® significantly reduces noise transmission from both human activity and machinery. Its low thermal conductivity helps maintain a building’s thermal envelope, improving energy efficiency and reducing heating and cooling costs.

Breathable by nature, it allows moisture to escape during humidity changes, preventing damp and mould while promoting a healthier indoor environment. Free from VOCs and chemical binders, WHEATEX® not only supports sustainability but also enhances indoor air quality — making it a smart choice for future-focused construction.

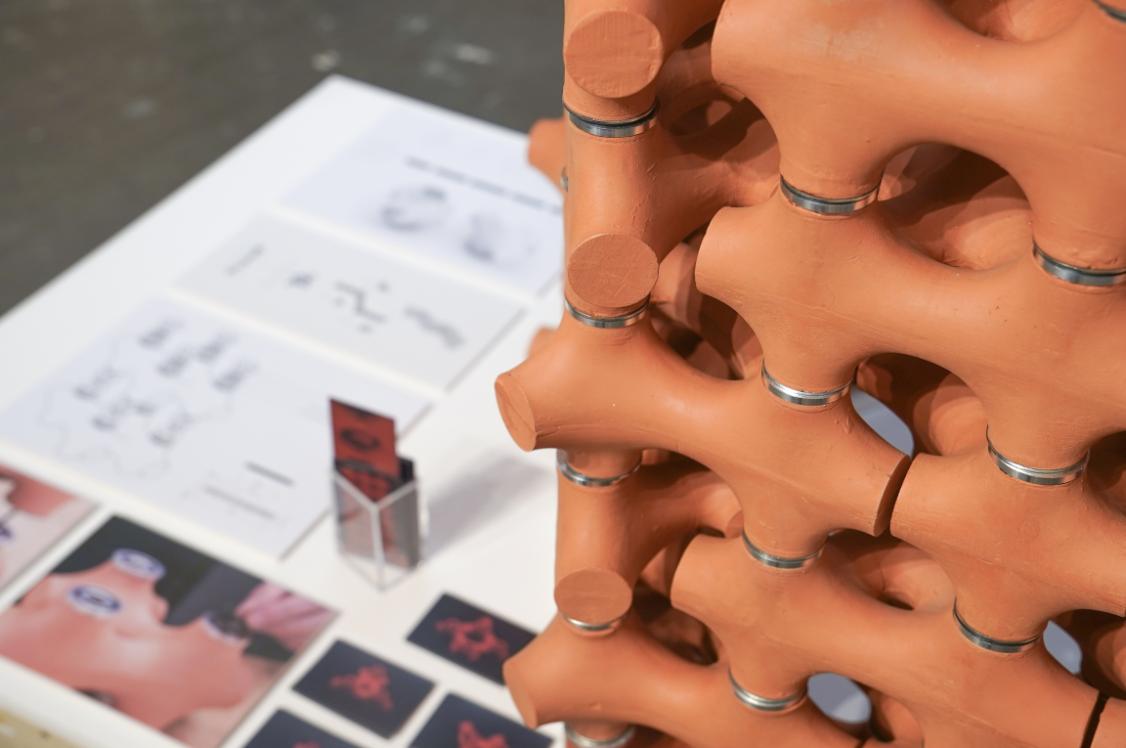

Microbiome Modulators. Image credit: Aileen Hoenerloh

Aileen Hoenerloh + Richard Beckett, Beckett Lab, UCL - Microbiome Modulators

Beckett Lab specialises in bio-design based at The Bartlett School of Architecture and researching probiotic interventions for the indoor microbiome.

Microbiome Modulators explores the intersection of design, microbiology, and material science through a series of 3D-printed probiotic ceramic wall tiles. Developed using red terracotta and white earthenware, the tiles are designed to house bacillus subtilis, a bacterium that is safe for humans, but is able to inhibit the growth of antibiotic-resistant pathogens.

Fired at low temperatures to maintain porosity, the ceramics are inoculated with the good bacteria, enabling them to serve as living, bio-receptive surfaces. The tile geometries are crafted through 3D printing and designed to shield the bacteria from harmful UV exposure and temperature fluctuations, creating shaded niches and airflow-guiding forms to enhance survival and controlled dispersion.

Invasive Bio-Resin. Image credit: Austėja Platūkytė

Austėja Platūkytė - Invasive Bio-Resin, SeaLeather, EcoBoards

Austėja Platūkytė is a material-design researcher, working in between the disciplines of material design, science, technology and craft.

Invasive Bio-Resin is an ongoing material research project exploring the synergy of beeswax and pine resin with invasive Lithuanian plants, particularly Solidago gigantea Aiton. The result is a durable, waterproof, and thermoplastic biomaterial, expanding its functional possibilities. Unlike many organic composites, this hybrid material maintains structural strength while being fully remeltable and reusable, extending its lifecycle.

By repurposing invasive species, the project promotes sustainable resource use and rethinks traditional craft techniques. Invasive Bio-Resin showcases how organic waste can replace conventional raw materials like wood or plastic, reducing environmental impact while fostering innovative, contemporary interior design aesthetics.

SeaLeather. Image credit: Austėja Platūkytė

Decorative Eco Boards. Image credit: Austėja Platūkytė

SeaLeather is a biomaterial research project addressing Baltic Sea eutrophication through sustainable design. Inspired by NASA images of algal blooms, the project highlights how excess nutrients fuel uncontrolled seaweed growth, creating marine "dead zones."

During an art residency at KKKC, Austėja explored local seaweed species (Furcellaria lumbricalis, Cladophora glomerata, and Ulva prolifera) to develop SeaLeather—a biodegradable bio-fabric symbolising suffocating algae carpets. Created from washed-ashore seaweed, it naturally decomposes in hot water, leaving no ecological harm. By transforming marine waste into a functional material, SeaLeather rethinks resource use, raises environmental awareness, and bridges science with sustainable design innovation.

Sustainable, non-toxic, and biodegradable solutions for eco-friendly design, Austėja's Decorative EcoBoards and acoustic panels were created to provide healthier, environmentally friendly alternatives to conventional building materials. Developed in collaboration with Strato Homes, this project explores non-toxic, recyclable, and biodegradable solutions for construction and interior design.

Conversing with Matter.

Benedetta Pompili

Conversing with Matter is a material research project exploring the by-product of the treatment of asbestos as a filler and glaze for ceramics. As a grog, it strengthens the body of the clay while reducing the quantity of mined material needed. It can substitute 50% of the amount of clay.

The material exploration is presented in a set of 100 vessels and 450 wall tiles, configuring the architectural and insulating possibilities of the composition while in dialogue with the past uses of asbestos.

BIRDMIND. Image credit: Javier Herranz

BIRDMIND - RICE TAB

RICE TAB is a rice husk board made from agricultural waste leftover from rice production.

A disruptive, innovative, sustainable, and circular material for the construction and contract sectors. RICE TAB is available in 2710 x 1360 mm boards and in thicknesses of 10, 16, and 19 mm. It also has fireproof, water-repellent, and anti-fungal properties. A variety of finishes can be applied: varnish, lacquer, stain, screen printing, veneer, and microcement.

Other properties include: 100% recycled / 100% recyclable; formaldehyde-free; zero water footprint - consuming no water for its manufacture; zero deforestation -consuming no wood for its manufacture, only agricultural waste; water-repellent for humid environments, type P3, kitchens, bathrooms, cellars, etc; fire-resistant, on two ranges: Bs1d0 and Cs1d0; highly resistant to termites, woodworms, and fungi.

Cupsan. Image credit: Opendesk

Blast Studio - Cupsan + Tree

Blast Studio is a London-based company transforming urban waste into high-performance biomaterials for interiors, including panels and furniture. The team developed Cupsan, a durable material made from London’s discarded coffee cups and bonded with a starch-based binder, using zero plastic or resin.

Collected in the city, the cups are transformed into a material that can be cut and sanded like wood, with a terrazzo or natural stone-like finish. Blast Studio’s work has been exhibited in major museums worldwide, and they were finalists for the 2022 Loewe Craft Prize, redefining waste as a resource through innovation and sustainable design.

Tree. Image credit: Paola Garnousset

SeaWood Materials. Image credit: SeaWood Materials

Blue Blocks - SeaWood Materials

SeaWood Materials transforms seaweed and leftover plant fibre from horticulture into beautiful, functional biomaterials.

A strong, versatile board that carries the warmth of nature into our living spaces, SeaWood Materials re-imagine seaweed and leftover plant fibre into natural and uniquely textural materials with the potential to replace conventional composites.

Sustainable and connected to the earth, SeaWood Materials can be applied to furniture, panels, or other design elements. It comprises a 100% natural, compostable and chemical free board material that can be used as a building material, for interior design products and acoustic wall panels.

The material is based on the results of Project Maasplaat that led to several product prototypes, tested and validated by the market. SeaWood is the next step towards realising our ambition to create massive positive climate impact.

The material will be in production in 2025, for current custom and made-to-order projects, please contact Blue Blocks directly.

Reclaim: Image credit: Caracara Collective

Caracara Collective - Reclaim

Caracara Collective is an experimental design studio that creates products and installations using biomaterials and biowaste.

Reclaim is a biodegradable material handcrafted from locally collected organic residues, primarily orange peel and fallen spruce needles. The biowaste is dried, ground and mixed with a natural binder. The material can be sculpted by hand or pressed in a mould for different applications in art, design and architecture.

The materials aim to reduce the harmful environmental impacts caused by toxic materials, irresponsible use of natural resources, and international shipping of raw ingredients. The materials are made from 100% natural ingredients, which means that after their useful life they can be composted or broken down to make new products.

Reclaim: Image credit: Caracara Collective

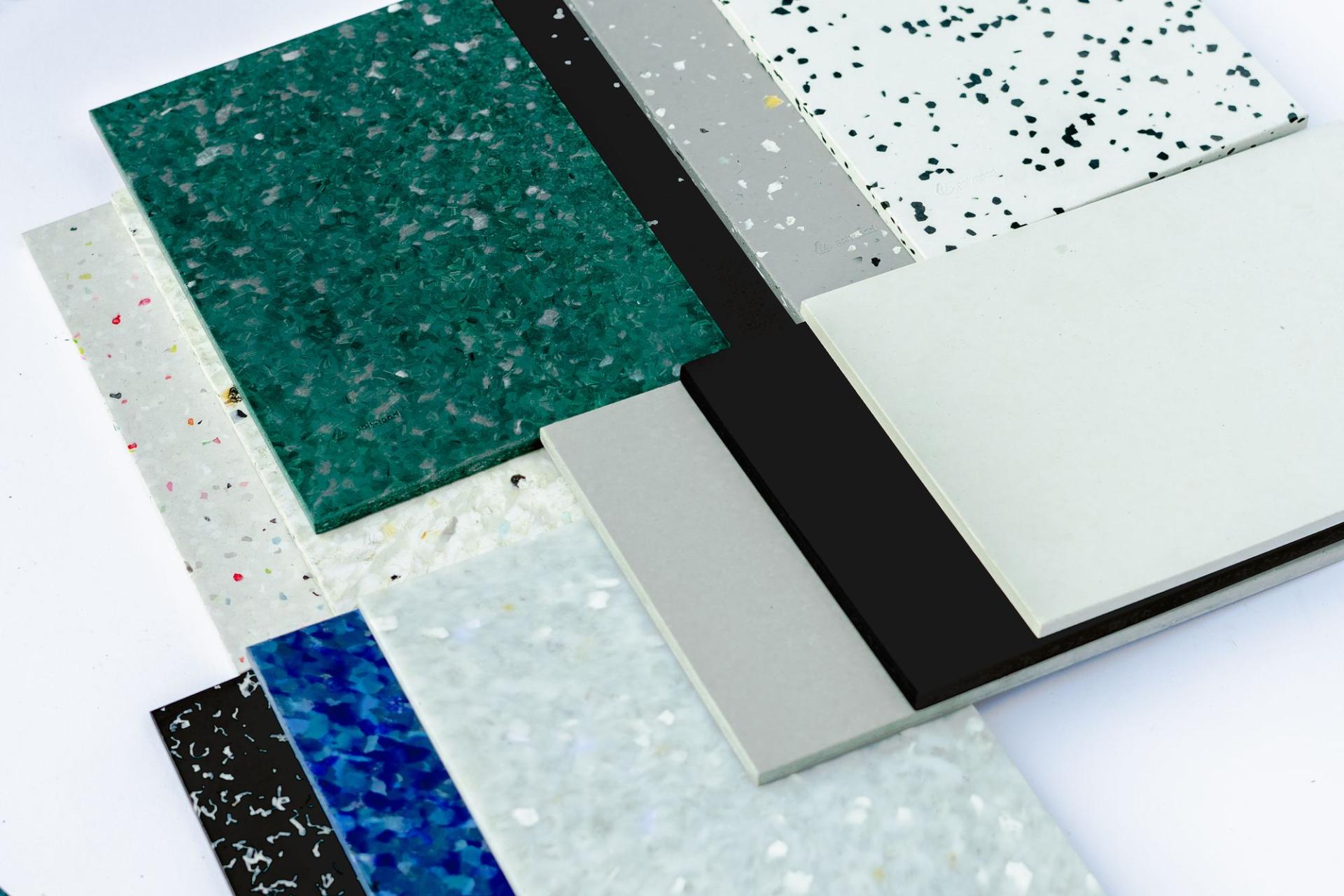

CDUK, Polygood®

CDUK - PaperStone® & Polygood®

PaperStone® is a paper composite surface material made from FSC® certified recycled paper and cardboard combined with a natural resin. PaperStone® is surprisingly tough, it is heat resistant and non-porous, making it suitable for a range of applications in commercial and residential spaces.

Hard as stone yet made from paper, PaperStone® is unique in its texture and appearance. There are eleven warm, rich and natural hues in the collection, with a soft and subtly variegated texture. Some colours have a solid, homogeneous appearance through the entire thickness, others are lighter and have striking ‘tone-on-tone’ striated edges, a unique feature that allows scope for a broad spectrum of surface design solutions. PaperStone® possesses an EPD, as well as FSC and NSF certification.

Polygood® is a surface material made from 100% recycled and recyclable plastic, the first material of its kind to attain Cradle to Cradle Certified® Bronze status.

Made from a single type of plastic, Polygood® is durable, waterproof and hygienic. It is available at scale to supply large commercial projects including furniture, retail fixtures and washroom applications.

Polygood® is produced from a wide range of post-consumer and post-industrial plastic waste sources: from refrigerators, to single-use cutlery; electronics to industrial consumables. There are over 30 patterns in the portfolio and each has its own unique back-story based on its material's origin, which influences its appearance. Some are playful with flecks of contrasting colour, others mimic patterns like terrazzo or organic textures. Certifications include an EPD and Cradle to Cradle.

CDUK - Polygood®

CDUK - Paperstone®

Clayworks, Rammed Earth: Image credit: Clayworks Licensed Photography

Clayworks - Rammed Earth & Natural Clay Plasters

Clayworks manufactures sustainable clay plasters, rammed earth and natural finishes - trusted by architects and designers for low-carbon, healthy interior and exterior surfaces.

Manufactured in Cornwall from abundant raw materials, Clayworks product range is amongst the most low carbon and healthy wall finishes available.

Clayworks clay plasters are a wall finish system, offering an environmentally friendly alternative to traditional materials. Crafted from a blend of unfired clays and sands, which are mixed with natural minerals and pigment, these plasters are known for their ability to regulate internal humidity.

Clayworks’ Rammed Earth finishes have been developed as an answer to the complex and technical challenges of building with monolithic mass, an ancient, natural construction method. Traditional rammed earth architecture requires many tonnes of compressed earth (normally at a width of 800mm) to create buildings with structural integrity, prohibiting its use and viability in most urban and retrofit contexts.

As an alternative to monolithic mass rammed earth walls, Clayworks Rammed Earth finishes can be applied as an entirely customisable 7-10mm thick wall build up, suitable for all wall and construction types. This innovation entirely revolutionises the way this natural building technique can be applied in contemporary buildings, delivering a cost effective and sustainable option.

Relevant Certifications include product EPDs, HPDs, VOC Emissions and Content Reports, Indoor Air Comfort Gold, Fire Ratings: Euroclass A1 & ASTM E84, and Planet Mark Certified Business.

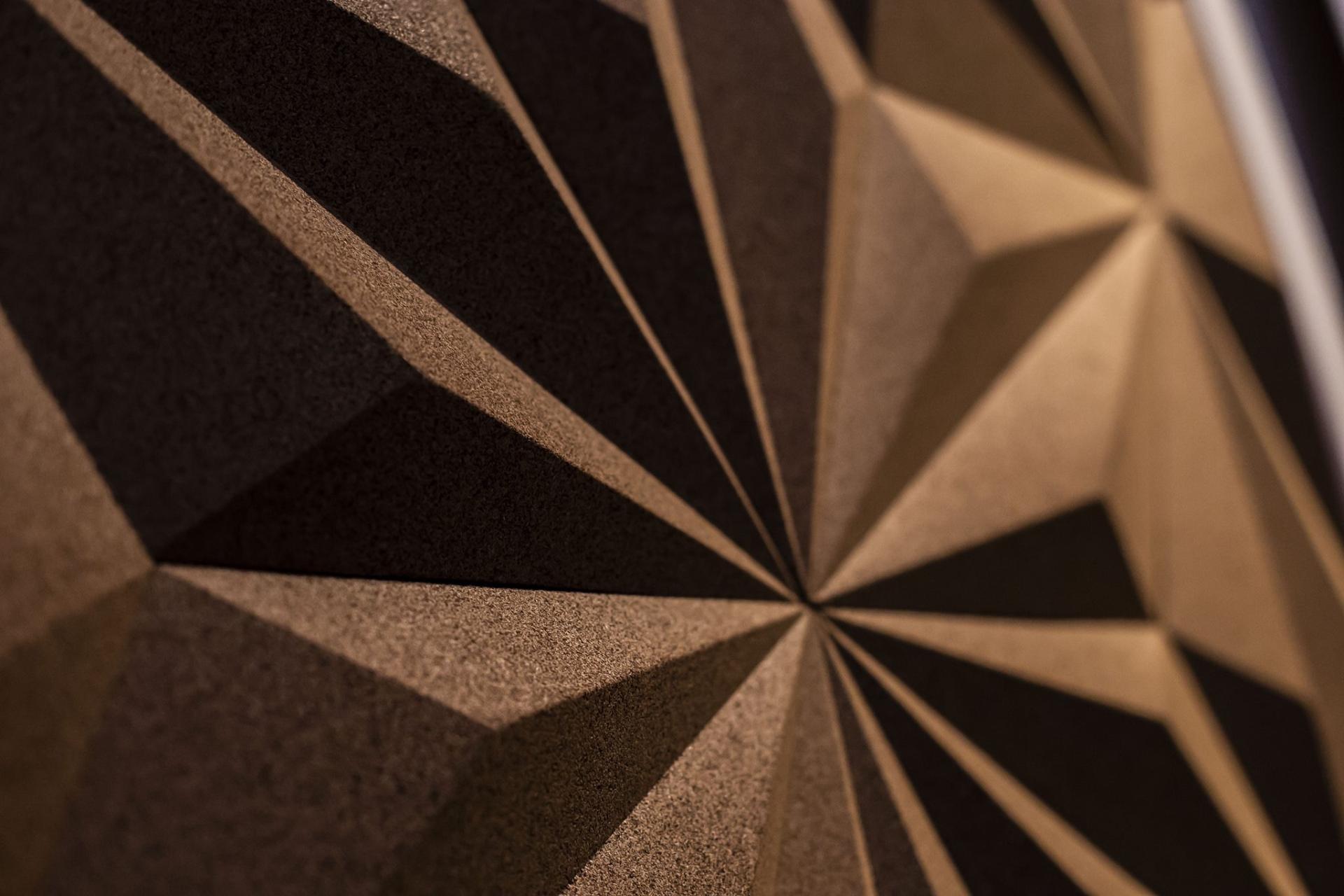

Cork Denim. Image credit: Dana Liv

CoFlora - Cork Wallpaper, Cork Denim, Cork Paint

CoFlora Design is a Spain-based supplier of fully biobased materials, harnessing one of nature’s most versatile and renewable resources – cork - in the manufacture of wallpapers, fabrics and coatings.

CoFlora sources cork bark ethically from regenerative forests in Portugal and Spain, transforming it into practical, high-performance solutions that directly reduce environmental footprint.

An organic bio-based wallpaper made from cork sheets and FSC paper, CoFlora's cork-based wallpapers can be utilised both in commercial and residential schemes.Its Cork Wallpaper is available in standard wallpaper rolls of 50-100cm wide, and in 5 or 10 linear metres.

Coflora’s Cork Denim is a biobased substitution for leather and an enhanced version of standard denim. It has a velvety feel and a visible denim ribbed surface. It's made by artisan communities of women in rural Portugal, who hand patch organic cork shavings onto a denim backing. Using organic denim of various colours and thickness types, from lightweight to heavyweight, this material is well pliable, sewable and easy to clean.

With a wide range of colour options and patterns available, Coflora cork denim can be utilised in interior projects - used as an upholstery material for furniture and interior panelling.

Cork Paint is a biobased covering made from organic cork granules. It comes in the form of a thick semiliquid paste, and can adhere to a variety of surfaces - including metal, wood, carbon, plastic - as a thin 3-5mm membrane/layer. Its application extends to both indoor and outdoor use including, furniture, walls, ceilings and building facades.

Dekiln, Eralith.

Dekiln - Cyalith, Eralith, Fabalith, StarCrete

Dekiln is a Manchester-based materials technology company developing revolutionary, low-carbon alternatives to traditional ceramic tiles.

Cyalith is a sustainable bio-based alternative to decorative ceramic tiles. Cyalith has a bioinspired structure akin to seashells, being comprised of over 90% naturally occurring calcium carbonate and a biopolymer binder. The biopolymer is obtained from photosynthetic algae (blue spirulina), and can be sustainably sourced as a byproduct from 3rd generation biofuels production.

Eralith is a sustainable bio-based alternative to decorative ceramic wall tiles made from over 98% recycled plaster (gypsum) along with a plant-derived binder. Taking inspiration from natural seashells and tooth enamel, Eralith meets the minimum performance requirements for ordinary indoor wall tiles. By avoiding kiln firing and other high-energy processes, Eralith tiles have a 20x lower CO2 footprint and 99% lower air pollution (PM2.5) emissions versus ordinary ceramic tiles.

Fabalith is a sustainable bio-based alternative to decorative ceramic tiles. It has a bioinspired structure akin to seashells, being comprised of over 90% naturally occurring calcium carbonate and a biopolymer binder. The biopolymer is obtained from aquafaba - the remaining broth after cooking chickpeas or other legumes.

StarCrete is a sustainable bio-based alternative to concrete with a substantially lower CO₂ footprint. It is made from sand and other mineral aggregates bonded together by potato starch. Due to strict regulatory requirements for structural concrete, the use of StarCrete is recommended only for indoor wall coverings (brick-slips, tiles).

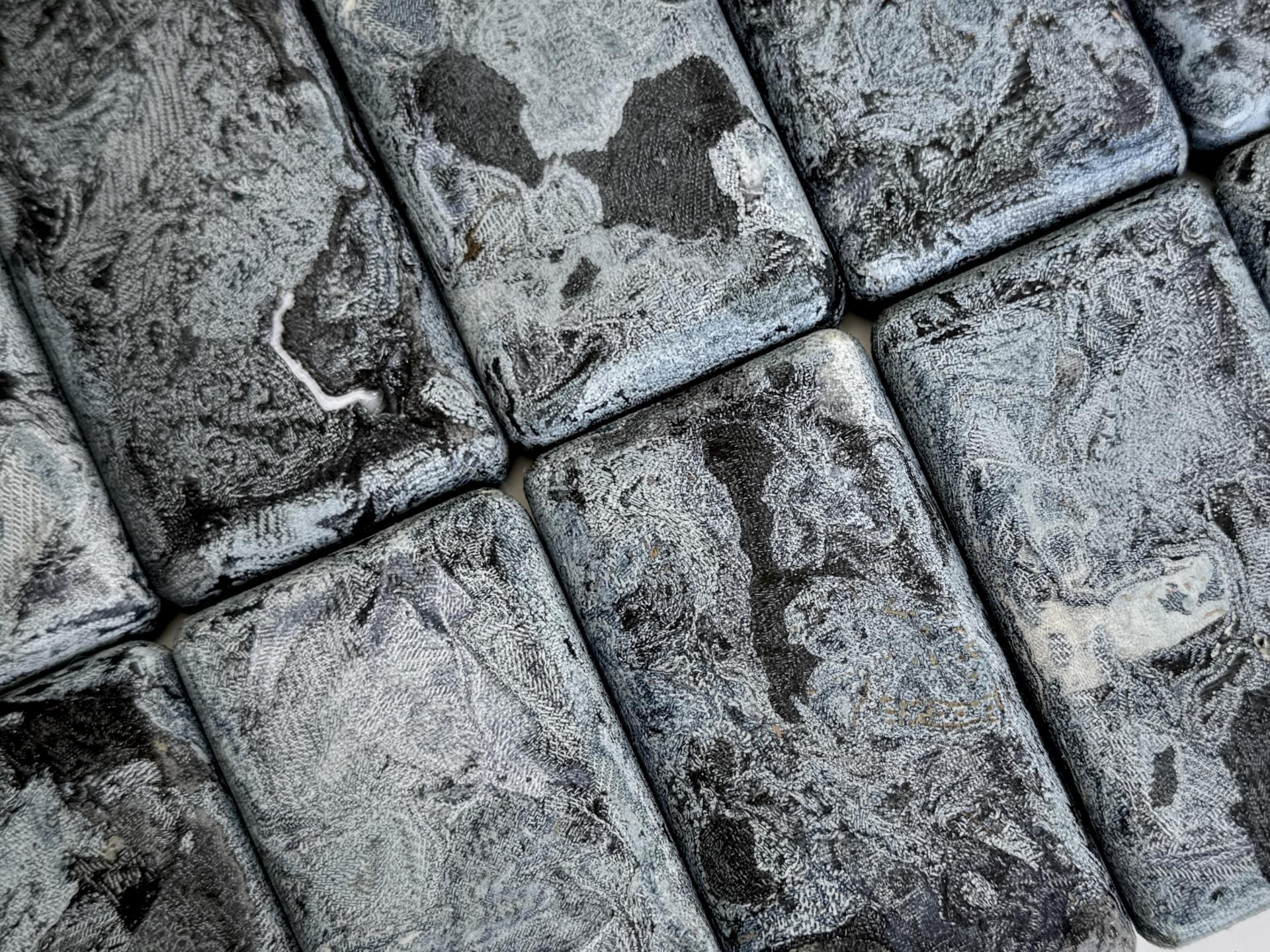

Denimolite.

Denimolite

Denimolite is a unique composite material made from fashion waste and denim off-cuts, combined with a plant-based bio-resin.

Collaborating directly with fashion brands to diversify their waste management processes, Denimolite transforms industry off-cuts into imaginative solid surface products.

The material is available in fully customisable sheets and panels, as well as a variety colours, finishes, sizes shapes, and thicknesses to suit a myriad of built environment based projects.

Disrupt. Design Lab, CyanoGems. Image credit: Haim Singer

Disrupt.Design Lab - CyanoGems

CyanoGems integrates carbon-fixating, biomineralising cyanobacteria into sand-based, 3D-printed scaffolds to create regenerative architectural materials.

Positioned within net zero and circular economy frameworks, the project introduces a design-led workflow for microbial activity at a built environment scale.

At its core is microbial biocementation, a process in which microbes enhance material strength through calcium carbonate precipitation, while actively sequestering CO₂.

CyanoGems proposes a biologically informed approach to additive manufacturing, where photosynthetic activity and structural integrity are enhanced by aligning geometric design with microbial performance.

The project offers a new approach for environmentally attuned architecture, where biology, design, and material production converge through co-fabrication with microbes.

Disrupt. Design Lab, CyanoGems. Image credit: Haim Singer

Exhibited at the Triennale Milano exhibition in Italy, under the theme “We the Bacteria – Notes Toward Biotic Architecture,” CyanoGems explores a bold vision for sustainable construction that is carbon fixating - effectively acting as a living, renewable alternative to traditional cement.

The project team behind CyanoGems includes the Faculty of Architecture and Town Planning; PhD candidate Perla Armaly-Bathish, Master candidate Yuval Berger and Asst. Prof. Shany Barath, and the Faculty of Biotechnology and Food Engineering; Dr. Lubov Iliassafov and Prof. Yechezkel Kashi.

EcoCocon straw panels. Image credit: EcoCocon

EcoCocon - Straw-based construction system

Made from natural materials and enabling energy-efficient living, EcoCocon is an innovative straw wall system that is revolutionising the construction sector.

EcoCocon panels are made of 98% natural renewable materials. And making them as close to nature as possible results in high indoor air quality with no harmful substances emitted.

The entire system is permeable to vapour – it allows excess humidity to escape – and with no thermal bridges and airtight, it leaves no space for draughts or mould. Natural materials create a healthy indoor microclimate with even temperatures – warm in winter and cool in summer.

Relevant certifications include: Cradle to Cradle Silver certified, Passivhaus component Certified, FSC timber. It also possesses an available EPD.

The panels have excellent sound insulating properties - resistance to the passage of sound of 54 dB. This greatly exceeds the standard requirements and results in exceptional acoustic comfort.

Contrary to popular belief, straw and wood buildings resist fire very well. The straw in its panels is compressed at a density of 110kg/m³, leaving no space for oxygen that would fuel the fire. Straw has a high content of silica, a natural fire retardant. When burning, both materials create a charcoal insulation layer on the surface that protects them from flames. Combined with clay plaster, its panels are rated to withstand two hours of intense fire according to the REI 120 and REIef120 certifications, meeting strict fire safety requirements.

An average EcoCocon panel is composed of 10% timber and 89% straw. The wood comes from sustainable forestry and the straw is sourced at local farms. Used in their raw states, the production process demands very little primary energy. To protect world’s forests from over-exploitation, the system is designed to use as little wood as possible – just enough for it to be load-bearing.

Both materials sequester large amounts of CO₂ through photosynthesis over their lifetime.This CO₂ is then safely stored in the construction resulting in a highly positive climate impact. Panels in a typical house with an external wall area of 130 m2 sequester more than 12 tons of CO₂e.

By replacing carbon-intensive materials such as concrete, bricks or polystyrene, as well as saving carbon in operations, EcoCocon’s real contribution towards the climate becomes even more significant.

EcoLattice - EcoLattice Foam

EcoLattice is a 3D-printed, lattice-based foam made from recycled Theamoplastic Polyurethane (TPU) - engineered for circularity, comfort, and performance.

Unlike conventional PU foams, it eliminates adhesives, waste, and landfill challenges through a fully recyclable closed-loop system. Using pressure data and generative design tools, EcoLattice translates real human postures into adaptive structures that enhance breathability, support, and durability.

Built from recycled elastomers, its foams are designed to last longer while maintaining their strength, comfort, and performance over time.Its geometry-driven design enables lightweight strength, precision comfort, and mass customisation without moulds or prototypes. Fire- and water-resistant, remeltable, and reprintable, EcoLattice redefines foam manufacturing delivering a smarter, sustainable alternative for furniture, mobility, and wellness industries.

EcoLattice: Spin stool

Local London hardwood timber. Image credit: Fallen & Felled

Fallen & Felled - Hardwood timber

Fallen & Felled transforms trees felled in and around London into high-quality timber and furniture, giving urban trees a second life.

By salvaging and processing local hardwoods – such as London plane, elm and beech – Fallen & Felled provide architects, designers and makers with a sustainable material, minimising waste and keeping carbon embedded in the timber.

Where necessary, it also sources oak and ash from sustainably managed woodlands near London. Fallen & Felled approach reduces reliance on imported timber, supports biodiversity and celebrates the unique character of city-grown wood. It prioritises local sourcing, carbon-conscious production and circular design principles.

All timber is sourced from in and around London, tracked to location and processed locally. While not FSC-certified, its supply chain is transparent and provenance is documented.

Forbo Flooring Systems: Marmoleum

Forbo Flooring Systems - Marmoleum & Furniture Linoleum

Marmoleum is Forbo’s natural linoleum flooring solution featuring up to 98% natural raw materials, including rosin, wood flour, linseed oil, jute and limestone. Cocoa shells are an additional natural byproduct used in the Marmoleum Cocoa rang, upcycled from the waste from the chocolate making industry.

These raw materials are obtained from their natural habitat, where they grow and renew themselves, often in just 12 months. With a proud heritage dating back to over 150 years, the weighted average of the Marmoleum product range is climate positive (cradle to gate), without any need for carbon offsetting.

For every m² of Marmoleum produced, 668g of carbon is removed from the atmosphere. Renowned for durability, Marmoleum is a high-quality sustainable flooring solution with innovative designs for various commercial settings.

Furniture Linoleum is a high-quality, natural surface material that emphasises elegance and sustainability. Climate Positive (cradle to gate), without offsetting, and made from natural ingredients like linseed oil, wood flour, pine rosin and limestone, its matte finish and soft texture can be applied to transform any surface, whether that is furniture, kitchen cabinetry, doors or much more.

Furniture Linoleum not only stands out for its beauty but also for its purity, offering a sustainable alternative to synthetic materials.

Forbo Flooring Systems: Furniture Linoleum

FRICKS, Upcycled Foam Bricks. Image credit: FRICKS

FRICKS - Upcycled Foam Bricks

FRICKS Upcycled Foamed Bricks reimagine the traditional brick through circular design, digital fabrication, and material innovation.

FRICKS transforms construction and demolition waste into lightweight, high-performance geopolymer bricks with expanded volume, low embodied energy, and enhanced thermal insulation.

Cured at ambient temperature and compatible with 3D printing or casting, FRICKS requires no firing and adapts to complex geometries. A 1:1 prototype wall, exhibited at the 2025 Venice Biennale, demonstrates its modular logic and expressive potential.

FRICKS offers a scalable system for regenerative architecture, where materials are not discarded, but revalued, reconfigured, and reintegrated into the built environment.

FRONT®, Paper Waste Panels. Image credit: Alted Materials

FRONT® - BioBasedTiles, Pretty Plastic Panels, Paper Waste Panels, WasteBasedBrick, WasteBasedSlips

FRONT® is a curated platform for sustainable building materials. Working closely with innovative producers, FRONT® brings together a growing collection of materials made from waste and renewable resources. Each product is selected for its potential to reduce environmental impact without compromising on quality or design.

BioBasedTiles are the first ever tile that grows with the help of bacteria. 20% lighter than a concrete block, but three times stronger, and not requiring kiln firing, BioBasedTiles lower CO₂ and are available in two colours and two finishes. Suitable for both exterior and interior applications.

Pretty Plastic Panels turn 100% recycled post-consumer PVC waste into innovative facade cladding. These durable, fire-resistant panels feature a unique, varied appearance and are designed to withstand the elements.

Demonstrating the potential of recycled waste in design, this product comes in three distinct shapes—diamond, square, and rectangle—along with four colour options and three tonal variations. Available in a single size, each panel features a uniquely textured surface, making every piece one of a kind.

FRONT®, Pretty Plastic Panels. Image credit: Maarten van Apeldoorn Fotografie

Pretty Plastic Panels are designed for easy disassembly and reuse. When they reach the end of their lifecycle, they can be fully recycled again.

Paper Waste Panels are decorative, waste-based, fully recyclable and non-toxic. A balance of aesthetics, performance and the lowest ecological impact.

In Europe alone, paper mills generate 11 million tonnes of industrial fibre waste from the paper industry annually. These panels transform industrial waste fibres from the paper industry into fully recyclable boards for interior use that would otherwise end up in a landfill. For every 100m² Paper Waste Panels, 722 kg of landfill waste gets upcycled.

Designed to be durable and versatile, each panel comes in three different textures and five standard colours to match any interior aesthetic.

FRONT®, BioBasedTile. Image: Nienke Krook credit:

The WasteBasedBrick proves that it’s possible to build high-quality, aesthetic structures from waste. It also serves as the source for the WasteBasedSlip, a thinner, cut version of the brick designed to further reduce materials.

Made from at least 60% C&D waste, WasteBasedBricks upcycle 91 kg of waste per square metre. These sustainable building materials are suitable for interior and exterior use, including facades, walls, furniture and flooring. They are available in various textures and colours and custom shapes and sizes.

The WasteBasedSlips are cut from WasteBasedBricks, making them not only waste-derived but also resource-efficient. They significantly reduce material usage while preserving the durability and aesthetic appeal of traditional masonry facades.

Made from at least 60% C&D waste, WasteBasedSlips upcycle 22 kg of waste per square metre. These sustainable building materials are suitable for interior and exterior use, including facades, walls, furniture and flooring. They are available in various textures and colours and custom shapes and sizes. WasteBasedSlips can also be implemented in dry-stack solutions.

Georgie Gerrard. Big. by Nina+Co - Credit: Anna Batchelor

Georgie Gerrard - Sculptural mycelium objects and furniture pieces

Georgie's work is heavily focused on process and material choice. A core element of her practice lies in choosing materials responsibly, considering their environmental impact and lasting effect post-use.

Her graduate project, 6 Locations is a collection of sculptural vessels grown from mycelium, her first exploration into this sustainable material. Each mycelium sculpture is based on a place significant to Georgie and her family - Devon, Surrey, Dorset, Bolton, Leicestershire and Bolivia - and grown using substrates connected to those regions, including cotton, alpaca wool, sheep wool, charcoal, straw and locally dug clay.

Commissioned by Nina+Co, Georgie created three sculptural plinths in mycelium for Big., a beauty store in Hackney designed with a material palette inspired by natural skincare ingredients such as clay, seaweed and mushroom extracts. For the launch of &Soul’s first site in Southall, a co-living conscious community, Georgie was commissioned to create bespoke mycelium furniture and sculptural pieces.

Giles Miller Studio - Coffee

Giles Miller Studio - Wine, Hemp, Coffee, Tobacco, Garlic, Charcoal

Giles Miller is an acclaimed London-based artist and designer, specialising in the development of innovative surfaces, materials and sculptural artworks.

In collaboration with HighSociety, Giles Miller Studio offers a range of eco-friendly signature tile designs crafted with by-products of wine, hemp, coffee, tobacco, garlic and charcoal from vodka production.

These by-products are collected from small local businesses and then formed Studio’s ‘Fin’ and ‘Penny’ tiles using FSC virgin cellulose as a binder. These tiles are water-repellent, durable, non-toxic and fully biodegradable (UNI-EN-ISO 14855-2:2018 standard).

The backing for the eco range tiles is ECOR - a high performance, sustainable green building material made from waste fibre, water, and heat. That’s it. It is 100% bio-based, 100% comprised of recycled waste materials, 100% recyclable, and is cradle-to-cradle compliant.

Granby Workshop - Ace + Tate

Granby Workshop - Granby Rock, Brick + Slate Terrazzo

Granby Workshop is design-led manufacturer of recycled tiles and architectural surfaces based in Liverpool.

Its products are designed through extensive material investigations. Focused on the creative potential of manufacturing and use techniques that introduce chance and randomness to the production line, no two products are ever the same.

Granby Workshop's unique ceramics make distinctive and playful additions to buildings and interiors all over the world.

Granby Rock is a bold, marbled recycled terrazzo made by combining crushed recycled aggregates, pigment, sand, cement and GGBS - a byproduct of steel production. Granby Rock is handmade using a traditional bench casting process.

Each mix is individually prepared, poured into formwork, reinforced with stainless steel rebar and allowed to cure for 28 days. Once a slab has reached full hardness, we grind and polish it using diamond pads to reveal its unique surface.

Encaustic Tiles are a modern reinvention of the traditional coloured ceramic floor tile. Made using a high performance, vitreous clay body with 72% recycled content, they are formed by hand in large clay blocks before being sliced and flattened into shape using a 60 tonne hydraulic press.

A spin-off from its original Granby Rock recipe, a new recycled Brick + Slate Terrazzo is a floor tile produced using recycled brick, terracotta tile and roofing slate. The tiles were developed in collaboration with a local terrazzo manufacturer in the North West.

The exotic imported marble chippings normally used in terrazzo have been replaced with by-products from local industry. Crushed waste from brick and tile producers is mixed and cast with sand and cement. The tiles are ground and polished, revealing a speckled light grey base decorated with fragments of red and blue.

Greenstep

Greenstep - Consultants and distributors of sustainable materials for building and interiors

Cork External Facades are 100% natural, available in an extensive range of material thicknesses, including a flat standard board face or six profile patterns. Cork facade can also be specified for a bespoke appearance, with the ability to produce in custom patterns and shapes.

The expanded cork insulation is a sustainable material for sustainable construction, with 100% natural process in which only cork is used as raw material. It has a high performance in thermal, acoustic and anti-vibration insulation, especially suitable for use in external and internal walls, slabs and floors, roofs and ceilings.

NATURALS is a collection of elegant natural cork floors for use in high-end residential and commercial interiors. Available as both a floating floor and glue-down option, the extensive range features multiple textures and colours. A high performance surface finish provides excellent wear and product longevity.

CORK STRIPS INFINITY is a cork wall for internal use, composed by a series of horizontal stripes and form a continuous pattern that - through its volume - create fantastic optical illusions and light effects. CORK STRIPS INFINITY allows combinations to be made in different orientations and different colours.

Hannah Elisabeth Jones

Hannah Elisabeth Jones - BioMarble, Lliw Lleol, 100% Grass

Hannah Elisabeth Jones is a researcher, educator and multidisciplinary artist-designer specialising in bio-based materials and organic colour.

Hannah has an innovative approach to craft and textiles, blending an interest in natural materials with an ethical commitment to developing an ecologically sensitive practice and a strong visual aesthetic.

BioMarble is a lightweight and flexible material with a unique surface pattern, but most importantly, it is made from waste paper mixed with natural ingredients. BioMarble can be naturally or synthetically dyed and the material was officially awarded a UK patent (granted in 2020). Laser cut units of BioMarble can be stitched together to form 3D installations for an interior wall or floor surface, or alternatively BioMarble can be layered with other materials to form a hard surface.

Lliw Lleol (Local Colour) is a natural dye database of locally sourced colour in North East Wales. This research maps out the seasons to show the cyclical journey of fully traceable colour through a material timeline. Jones collected 6 dyestuffs each month for a year and dyed 10 different unbleached materials per dyestuff, resulting in 720 swatches of colour data. Jones took a regenerative approach to foraging and only used a small quantity of berries or leaves from areas where they were prolific, to conserve the health of each plant.

Hannah’s work process is underpinned by an engagement with research across the arts, humanities and sciences. She was awarded a NWCDTP scholarship for her PhD Design at Manchester School of Art (2020-present) and awarded the Burberry Design Scholarship to study MA Textiles at the Royal College of Art (2018-2020). She graduated from the RCA with her final project ‘Lliw Lleol’ (Local Colour) – a comprehensive natural dye database, investigating colours obtained from locally foraged common plants and weeds.

Her latest project comprises regenerative materials made entirely from grass cuttings sourced by hand within North-West England. The materials do not contain any synthetic or natural binders. Unlike most other plants for fibres and trees for paper pulp, grass is a locally abundant resource and does not die when cut – but continuously grows. Once used, the materials can biodegrade and contribute to soil organic matter.

The fibreboard, paper and cordage have different properties and therefore could have varied applications. As part of her PhD research, Hannah will be testing the mechanical properties of the fibreboard in her University to compare against current single-use inner packaging materials like polystyrene and moulded cardboard.

HBBE

HBBE - The Hub for Biotechnology in the Built Environment - Healing Masonry

The Hub for Biotechnology in the Built Environment is a collective of bio-scientists from Northumbria University and architects, designers and engineers from Newcastle University - developing biotechnologies to create a new generation of ‘Living Buildings’ which are responsible and responsive to their natural environment.

Healing Masonry is an innovative project led by Dr Magdalini Theodoridou and developed in collaboration with an interdisciplinary team at the Hub for Biotechnology in the Built Environment.

It explores how bacteria can precipitate minerals within composites to self-heal cracks before they become critical. By combining heritage-inspired construction methods with emerging biotechnologies, it proposes sustainable, resilient alternatives for architecture.

Applicable to both contemporary and historic structures, the system supports adaptive reuse over new build. By extending lifespans, reducing material demand, and enabling bolder designs, Healing Masonry shows how living technologies can advance decarbonisation in the built environment.

HempWood

HempWood

HempWood® is produced using hemp and a soya based adhesive to offer a timber substitute.

The Hemp is organically grown, offering a sustainable solution to deforestation. 20% harder than Oak, HempWood® has a carbon negative footprint and is free from any toxic VOCs.

The flooring product consists of a 4-mm HempWood veneer bonded to a 12-mm hardwood plywood manufactured by Columbia Forest Products, also made with NAF soy-based adhesive resin. It is available in four different tones; Natural, Taupe, Ice and Granite.

A cradle-to-grave Life Cycle Assessment (LCA) was completed on HempWood® Natural Flooring in accordance with ISO 14040 / ISO 14044, and the study was reviewed for conformance with ISO 14044 and the PCRs. The product assessed was based on 2021 data from Fibonacci’s Murray, Kentucky, HempWood facility.

IndiNature

IndiNature - IndiTherm, IndiBreathe

IndiNature is pioneering the use of industrial hemp as insulation in the race to decarbonise the construction and building sector.

In February 2024 the firm reached an important milestone in becoming the first UK company manufacturing industrial hemp insulation to obtain a full agrément certificate from the British Board of Agrément (BBA).

This means the hemp-based products can be used by the housing and construction sectors at scale for both new build and retrofit projects as well as historic and listed buildings.

Jeffrey Miller - Credit: Sarel Jansen

Jeffrey Miller - From the Underground

From The Underground reimagines the iconic tiles of the London Underground by making them from the system's own waste.

Traditionally, tiles rely on virgin resources extracted through mining, yet this project employs materials generated directly by the network:

London clay unearthed during tunnel excavation and iron oxide dust created as train wheels grind against steel tracks. In doing so, it establishes a material continuity with the Underground's history while foregrounding the hidden costs of extraction.

The project proposes cycles of reuse as a means to transform urban waste into enduring architectural identity.

Kenoteq - K-Briqs

Kenoteq - K-Briq, K-Slip

Kenoteq is innovative and ambitious, aiming to become a global leader in the world of ultra-low carbon sustainable building materials, whilst providing local circular waste solutions which support local supply chains and drive down carbon emissions.

The team is revolutionising traditional brick-making methods. Recycled materials, no waste, no firing, fast local production.

Its products are grounded in science: with over a decade of research, development and testing the fully circular, patented, low energy production process allows Kenoteq to create its own low carbon products to a patented proprietary formation.

This fully circular process allows the creation of products fit for use within 24 hours of the processed waste arriving at the Kenoteq factory.

Koukos de Lab

Koukos de Lab

Koukoutsi Eco‑Material is a patented, earth‑inspired composite crafted in Lesvos from over 80 % olive‑oil waste - olive cores and pips - blended into a resilient bio‑resin matrix.

Available in Blonde Pip and Dark Core variations, it delivers rich, terrazzo‑like textures. Water-resistant, extra hard, and durable, Koukoutsi excels in furniture, flooring, wall cladding, countertops, and outdoor applications.

Produced in a low‑impact, slow‑design ethos, it supports repair, repurposing, and a circular lifecycle—bringing nature’s story into built environments. Koukoutsi stands out as a thoughtful choice for designers seeking sustainable aesthetics without compromising on performance.

Lionne Van Deursen - Biotic

Lionne Van Deursen - Biotic, LUNA

Biotic explores the potential of a biologically grown material, bacterial cellulose—a biofilm created by living microorganisms during fermentation.

The resulting material is translucent, flexible, biodegradable, and has leather-like properties. During growth, textures, translucency, thickness, and colour naturally vary, giving each piece a unique character. It can also be dyed with natural pigments and fruit-waste colours, creating diverse patterns and hues.

Biotic demonstrates how living materials can inspire thoughtful, sustainable design through craft, experimentation, and the material’s inherent possibilities.

Margent Farm

Margent Farm - BastBoard™, BastWave™

Margent Farm designs innovative materials from hemp that combine performance, aesthetics, and responsibility.

BastBoard™ is a flat versatile interior panel made from hemp fibre, already featured in Aesop’s first Cambridge store and soon in their upcoming Hong Kong space.

BastWave™ is an exterior cladding system, delivering durability, natural beauty, and reduced carbon impact for architectural applications.

Both products demonstrate how natural fibres can meet modern standards in construction and design without compromise. By transforming hemp into scalable, high-performance solutions, its reimagining the future of materials – rooted in nature, engineered for today, and built for tomorrow.

Mathilde Wittock - MWO Design - Soundbounce

Mathilde Wittock - MWO Design - Soundroot

Mathilde Wittock - MWO Design - Soundbounce, Soundroot

Mathilde Wittock - MWO Design - is an eco designer and material researcher with a focus on sustainable innovation. Originally from Belgium, she studied biodesign and industrial design at Central Saint Martins in London, where she developed her expertise.

Soundbounce is an acoustic surface made from repurposed tennis balls. Each ball is manually cleaned, dyed with non-toxic pigments, and slotted into a glue-free modular structure.

Designed to reduce noise pollution in shared spaces, Soundbounce transforms global waste into local, circular solutions. It absorbs up to 97% of sound at key frequencies, making it ideal for interiors where acoustic and visual comfort matter. The system is modular, reversible, and recyclable — blending environmental thinking with sensory design.

Soundroot is a bio-based textile material grown directly from the roots of fast-growing grasses into thin, flexible mats. Each mat exhibits unique textures and tones created through variations in growth and post-treatment conditions. Designed as a regenerative alternative to synthetic acoustic textiles, it merges design, biology, and sound science.

MIYUCA - Credit: FlipFlop Collective

MIYUCA - Laab, Salt Edition

MIYUCA specialises in creating handmade objects out of autumn leaves.

These products are called "Laab" meaning "leaves" in South Tyrolean language. Each piece reflects the beauty and diversity of nature, showcasing the artistic potential of natural materials.

In a society marked by waste, Laab is an alternative to conventional plastic products.

MIYUCA's Salt Edition is a new and exclusive material made with salt and gold - designed to elevate every space with a touch of luxury. Each panel is unique, reminiscent of elegant stone or marble with a sophisticated aesthetic.

Myceen

Myceen

Myceen is growing carbon-storing building materials combining mushroom mycelium and industrial by-products from wood and paper processing industries.

Furniture and design objects as its starting point allowed Myceen to prove its ability to produce complex objects with mycelium materials. Next up are high-performing insulation and acoustic materials for the carbon-neutral construction industry. Made scaleable with fully automated production technology.

With over a billion years of experience, fungi are far more advanced than humans. Therefore, it is crucial to learn from them to improve our lives. Our multidisciplinary approach combines nature’s intelligence with science and design, allowing us to create a cleaner and more responsible environment and products.

Mycelium, the core component of our novel materials, is the underground root system of mushrooms. This decentralised organ of fungi allows us to grow biodegradable materials. These materials can replace problematic plastics and composites. Additionally, they add value to organic industrial byproducts. The rapid growth of mycelium makes it ideal for large-scale production of industrial materials. Mycelium can bind loose matter into solid, high-performing, carbon-neutral materials.

MycoWorks

MycoWorks - Reishi™

Since its founding, MycoWorks has partnered with people and brands dedicated to achieving artisanal excellence and uncompromising quality in every product made with Reishi Fine Mycelium. It relies on the tools of biotechnology, manufacturing excellence and creative, master craftsmanship.

MycoWorks' heritage in art, design, and materials science is evident in the diverse range of innovators and leaders on its team.

They range from Fine Mycelium Experts—the world’s first master artisans in the craft and technology of Fine Mycelium—to its executive leaders with proven expertise in biomanufacturing, rapidly scaling new technologies and amplifying value through our collaborations and storytelling.

Zeefier - Credit: Lotte van Uittert

Nienke Hoogvliet - Zeefier

Zeefier supplies dyes 100% made of seaweed to leading partners of the textile industry across Europe.

Designer, Nienke Hoogvliet, creates textile dyes made entirely from seaweed. Unlike synthetic, petroleum-based colorants, our dyes are biodegradable, chemical-free, and produced without the need for fresh water, farmland, or pesticides.

With seaweed sourced from European farms and side streams, we offer a circular, scalable, and legislation-proof solution for the textile industry. Our dyes are already used on cotton, wool, silk, and linen, delivering a natural colour palette from sand and beige to ocher and green.

Designed as a plug-and-play system for dye-houses and mills, Zeefier enables brands to reduce their footprint while achieving vibrant, durable, and truly sustainable colours.

Marlene Stechl/onmatter/onmatter.eu

onmatter - HopfON Acoustic Panel

Every year, vast quantities of hop vines are left behind—once burned or composted, now transformed. onmatter harnesses the full potential of this overlooked biomass to create high-performance acoustic panels made entirely from hops.

Through its novel process, the plant’s own lignin—its natural binder—is thermally activated to bond the fibres, eliminating the need for synthetic adhesives or additives.

The result is a fully bio-based, compostable material with excellent sound absorption and a distinctly regional identity. Designed for interior architects, furniture makers, and sustainable builders, onmatter panels bring agricultural rhythm and material circularity into the built environment—100% hops, nothing else.

Organoid

Organoid

At Organoid® nature, design, and innovation come together.

Organoid® natural wallpapers and surfaces combine nature with modern design – for spaces that inspire. The CARPE DIEM wallpaper was honoured with the Green Product Award 2025 as a ‘Unique surface for all the senses’ – out of more than 1,500 submissions from 46 countries.

Naturally Innovative, the wallpapers are: sustainably & climate-neutrally produced; handmade in Tyrol; a unique sensory experience; versatile in application; allergy-friendly; award-winning.

Ottan

OTTAN - Eggy, Moon, Nuts, Nutty

Ottan develops durable and aesthetically pleasing bio-composite materials, and production systems for a net zero future.

The team up-cycles food and agricultural industries' waste and by-products to create stunning building materials, so that they can help to reduce excessive consumption of raw materials like wood and stone.

Ottan confidently offers sustainable material technologies for mega industries, with a primary focus on construction, furniture, and automotive.

Its innovative solutions are also compatible with jewellery, tableware, toys, and many other applications, providing a versatile and eco-friendly option for a wide range of industries.

Parkside Tiles + Alusid - MAS Tile

Parkside Tiles + Alusid - MAS Tile

This ceramic tile reduces CO₂ emissions by over 50%, is composed of at least 95% waste materials from multiple industries, and is 100% suitable for any design project.

Most of the world’s ceramic tiles use an industrial, energy-consuming process called spray drying to prepare the raw materials. The Skip Tile is different because it uses an innovative process: the traditional energy-consuming spray drying is skipped, and a unique low-energy dry granulation process is used instead, making Skip Tile one of the lowest-emission floor tiles on the market.

The 'Mas' Range is available in four colours: grey, ochre, red and charcoal.

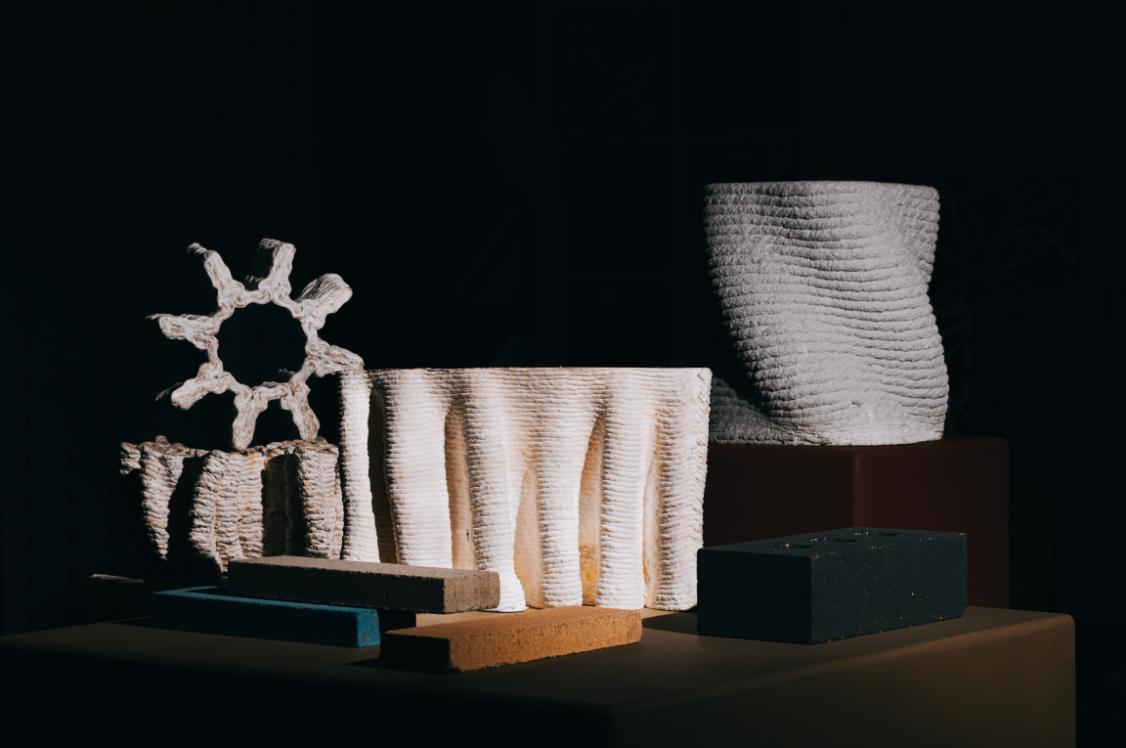

PrintCity - 3D Printed Concrete - Credit: Tim Ainsworth

PrintCity + Aaruga Selvaratnam UofM + PrintCity MMU - Low carbon 3D printed concrete

This innovative low-carbon 3D printed concrete, crafted using a 3-axis robot arm with a 20 mm nozzle, showcases exceptional mechanical properties. Designed to meet standard requirements for both compressive and tensile strength, this low-carbon concrete is ideal for robust structural applications. With a carbon footprint that is 44% lower compared to standard cement 3D printed concrete, this sustainable material paves the way for a greener future in construction.

Resilica - Recycled glass

Resilica® - Recycled glass

Resilica has established an outstanding reputation for supplying leading companies and specifiers with the finest recycled glass surfaces for office and commercial fit outs, and the residential market.

A specialist manufacturer and supplier of the UK’s first recycled glass surfacing material – Resilica gives specifiers and clients a more sustainable alternative to man made quartz worktops and natural stone surfaces.

It can also take waste materials from site at the strip out phase and re purpose them into new surfaces to be used within the new scheme.

Since 2001, Resilica has established an outstanding reputation for supplying the UK’s leading companies and specifiers with the finest recycled glass surfaces for office and commercial fit outs, and the residential market.

This success has been built on the team's ability to listen, interpret and produce the best sustainable surfacing solutions for their client’s projects, on time and on budget… every time.

Rosy Napper - ReCinder

Sara Howard - Circular Ceramics. Credit: Sara Howard & Kevala Ceramics

Rosy Napper - ReCinder

Rosy Napper is a ceramic material researcher and designer based in London.

ReCinder is a 100% recycled material made from waste ceramic and ash that has been diverted from landfill. It is a greener, waste-based alternative to industrially processed clay, eradicating the need for conventionally mined and environmentally damaging raw materials often used in ceramics.

The material is also versatile. As well as being suitable for tiling, furniture and tableware, it can be used for lighting due to its unique translucent quality.

ReCinder is the world’s first entirely recycled ceramic material currently on the market capable of translucency. Our range of lamps are made using ReCinder tiles and locally sourced reclaimed materials.

ReCinder also comprises a ground-breaking tableware collection handcrafted from ceramic waste, created through an exclusive collaboration between Rosy Napper and The Home of Sustainable Things. Ultra-local and sustainably produced, the range repurposes discarded, defective, and broken fired ceramics sourced primarily from producers and academic institutions across London, transforming them into the lowest-carbon tableware range on the market.

Serama Studio - Rameshwari Jonnalagedda - Minimal Matter with Red Terracotta Clay

Sara Howard - Circular Ceramics

Circular Ceramics is a fifteen piece tableware collection handmade from locally sourced materials destined for landfill. The clay body is made from 100% waste sourced from a ceramic factory's wastewater treatment system.

The glaze ranges from 30% - 100% waste, sourced from natural stone factory slurries, glass consumer waste retrieved from local rivers and glaze residue from ceramic factory production.

The hand-thrown stoneware forms are intentionally designed for longevity and are both microwave and dishwasher-safe.

Circular Ceramics is designing a new way of consuming that reduces the harm inflicted on our planet and preserves our natural resources, without compromising on design.

Serama Studio - Rameshwari Jonnalagedda - Minimal Matter with Red Terracotta Clay

Driven by the brilliance of natural efficiency, project Minimal Matter by Rameshwari Jonnalagedda translates the complex geometries of minimal surfaces into architectural forms that respond to environmental and functional demands.

Developed during her Master’s at UCL and advanced through her practice at EcoMatter Studio, the aim is to explore the potential of minimal surfaces—defined by their high surface area-to-volume ratio and cellular porosity—to create structures that balance material and structural efficiency.

Utilising 3D-printed red terracotta clay, the foundational idea is to create adaptable frameworks for diverse applications, from eco-conscious facades to biodiversity-supportive systems, adjusting geometry and cell type for each need. This method applies nature-driven strategies, envisioning a future that is responsive to its context.

Minimal Matter is a living framework shaped by the quiet intelligence of natural systems. Emerging from high surface area geometries known as minimal surfaces, this material explores how structure can be both efficient and open - strong yet soft, porous yet purposeful.

Created through 3D-printed clay, each form adapts to its surroundings, offering space for air, water, light, and life to move through it. Designed not as a fixed product but as a system that responds to place and purpose, Minimal Matter reimagines materiality as something alive , capable of shifting, hosting, and evolving with the world it inhabits.

SAPPA Acoustic Panels

SAPPA - Hemp Acoustic Panels

SAPPA acoustic panels represent the most innovative and sustainable solution dedicated to acoustic comfort.

Made from hemp, a rapidly renewable natural raw material, and natural mineral-based binder (cement-free). For interior use, walls and ceilings.

SAPPA's products are made from chopped stem chips of the hemp plant. These chips are industrial debris left over from the plant as a result of the process of removing the fibre thus producing a zero waste product.

The resulting material creates a negative cycle of CO₂ emissions, it produces no garbage, and is easy to recycle. A complete Cradle-to-Cradle design.

Søuld - Eelgrass

Søuld - Eelgrass acoustics

Søuld is a Danish material manufacturer committed to providing forward-thinking designers, builders and end-users with eco-friendly, recyclable and carbon-storing building materials made from eelgrass.

Founded in 2010, Søuld’s mission is to produce functional, sustainable and beautiful alternatives to traditional building materials that can improve sustainable development in the construction industry, whilst also improving human health and well-being.

For over a decade Søuld has collaborated with ecologists, manufacturers and designers to develop acoustics from eelgrass—an abundant, renewable local sea plant with deep roots in Danish culture—to offer the industry a high performing alternative to synthetic options. Søuld’s work has led to the revitalisation of the 400-year-old eelgrass tradition, to the protection of the eelgrass ecosystem and to the material’s optimisation for sustainable 21st Century building.

Engineered for residential and commercial spaces, Søuld’s eelgrass products create calm and comfortable indoor atmospheres that connect with nature through organic, tactile surfaces and the subtle scent of the sea. Søuld’s products offer excellent acoustic, thermal and moisture regulating properties, are highly resistant to fire, contain no toxic chemicals, release extremely low emissions and reduce carbon footprint by serving as CO₂ storage.

Strawcture Eco - AgriBioPanel™️

Strawcture Eco - AgriBioPanel™️

Strawcture Eco's mission is to research, manufacture and promote plant-based building materials to decarbonise the built environment.

AgriBioPanel™️ is Strawcture Eco's first proprietary product which is made of 95% agricultural residue. The engineered panel is insulating, has a low ecological footprint, and offers a versatile surface for any kind of desired aesthetic.

AgriBioPanel™️ can be used for making load bearing drywall partitions, cladding, false ceilings, furniture and for bespoke acoustic solutions.

The panels are Indian and European Standards Certified, currently being used in India, UK, Italy and Singapore.

Each sqm of an 11mm AgriBioPanel™️ stores 3.2 kg of CO₂.

Studio Lotek - Seacrete

Studio Lotek - Seacrete

Seacrete by Studio Lotek is a biomaterial derived from locally sourced oysters and mussels around the Dutch coast, inspired by traditional shell lime architecture.

Designed to integrate with rising sea levels, it fosters biodiversity by transforming structures into evolving biotopes.

As the material dissolves, Seacrete enriches marine ecosystems and minimises environmental impact. Its adaptive design embraces the natural occurrence of erosion.

For the Negotiating Boundaries research project (funded by the Creative Industries Fund NL), Seacrete shares both our bio-based and bio-receptive categories best In this context, the material is designed and positioned to facilitate other life forms, particularly in ecological and marine environments. For this application, Studio Lotek is testing ecological performance with NIOZ (the Dutch Royal Institute for Sea Research), for example, in tidal pool installations where it supports both human use and ecosystem growth.

By merging ecological knowledge with material science, Seacrete could be a sustainable alternative to conventional building materials, promoting regenerative architecture that supports both human and nonhuman life.

Studio Sarmīte - PineSkins

Studio Sarmite - PineSkins, (Un)woven

Studio Sarmīte is a materials design and research studio focussing on transforming industry waste and its byproducts into new closed-loop concepts.

PineSkins is a versatile, leather-like material made of inner bark of pine trees, a by-product of the tree cutting industry. Ranging from earthy brown to pink, deep terracotta to ash-grey and a scent of wood, PineSkins carries a unique appearance that feels familiar yet unseen. In order to become flexible, the freshly harvested bark is treated with a bio-softening solution and enhanced with colour pigments and natural wax.

On a broader level PineSkins looks at the resources of forests. It aims to create alternative production paradigms for the tree cutting industry with less emphasis on timber production.

(Un)woven is a biotextile made of inferior textile fibres, created as an alternative to the flawed traditional textile recycling process. A unique production method turns inferior mixed blends into a lightweight biotextile suitable for interior, furniture and product design applications. Emphasising recyclability over longevity, the sturdy material can be recycled at the end of its life and repurposed for new production cycles over and over again.

Takizawa Veneer Manufacturing & Drill Design - Paper Wood

Takizawa Veneer Manufacturing & Drill Design - Paper Wood

Crafted in Japan, this distinctive material combines native hardwood with specialty recycled paper to create a bold, durable end-grain edge.

Its richly layered cross-section reveals organic textures and subtle tonal variations, offering both tactile and visual depth.

Ideal for furniture, interior products, accessories, toys, and custom fixtures, it brings a warm, natural character to contemporary design.

Rooted in circular thinking, it reflects a commitment to sustainability without compromising on aesthetics. Each piece tells a story of craftsmanship and innovation—where tradition meets modern values.

A perfect choice for designers seeking authenticity, material presence, and expressive colour in their work.

The Hemp Block Company

The Hemp Block Company - Hempcrete

The aim and mission of The Hemp Block Company are to reduce the amount of carbon produced by the construction industry by replacing high embodied carbon materials, like concrete blocks, cement and petroleum based lightweight insulation with natural hemp blocks.

Hempcrete can be a significant player due to the amount of high embodied carbon materials it can replace. It is made from 100% natural materials, helps control humidity within a property and reduces energy usage.

Thermafleece

Thermafleece - CosyWool, UltraWool

Thermafleece is suitable for traditional building and modern construction. Creating more breathable, sustainable and healthy structures.

At Thermafleece, the home of British sheep's wool insulation, the team has 20+ years of research and development experience. Its products optimise the properties of natural and recycled fibres to benefit clients, buildings and the environment.

Proud supporters of British farming, Thermafleece CosyWool and UltraWool products are made in Britain from British sheep’s wool - a natural fibre that saves energy in buildings.

Tŷ Syml - Credit: Justin Chung

Tŷ Syml

Tŷ Syml, a multi-award winning design company based in Pembrokeshire, West Wales, was founded by brothers Adam and Daniel Davies with a visionary approach to regenerative design.

The company's core mission is to innovate using locally sourced "waste" materials, thereby mitigating the adverse effects of business and consumer activities on society, economy, and the environment.

At the heart of Tŷ Syml's philosophy is a consideration of a product's entire life cycle, from material sourcing and manufacturing to end-of-life disposal. This comprehensive approach aligns with their belief that future design and architecture should 'design out' waste, creating systems where the concept of waste becomes obsolete.

Experimentation is crucial to Tŷ Syml's development process. By extensively exploring new materials and their properties, the Tŷ Syml gains a deep understanding of each material's capabilities and potential applications. This experimental approach often leads to unexpected and innovative outcomes, as the materials themselves guide the evolution of products.

Sugarcrete - Credit: Megan Jones

University of East London - Sugarcrete®

This low-carbon material is just a part of the project's ambitions. The project seeks to offer different viable, sustainable, and safe construction solutions, using bio-waste as the core resource, to enhance community wellbeing and security.

The project has been developed as a collaboration between the UEL MArch Architecture programme and the Sustainability Research Institute (SRI) with the support of Tate & Lyle Sugars and Chemical Systems Technologies (India) Pvt. Ltd.

The aim of the project is to develop ultra-low carbon building components using sugarcane bio-waste (bagasse), allowing the storage of biogenic carbon from fast-growing plants in construction materials as an effective strategy to delay carbon emissions.

Sugarcrete® is not patented. It is purposely ‘open access’ to establish partnerships to produce new bio-waste-based construction materials where sugar cane is grown, and the benefit is greatest.

Graphene concrete - The Graphene Engineering Innovation Centre

University of Manchester - Graphene concrete

The Graphene Engineering Innovation Centre (GEIC) at the University of Manchester is advancing sustainability in the construction industry by integrating graphene into cement and concrete.

These innovations reduce the carbon footprint of construction by decreasing the need for materials like concrete and steel. From lab experiments to large-scale site trials, the GEIC has found its graphene admixtures to deliver improvements in compressive, tensile and flexural strength in concrete, accelerated curing time, crack reduction and reduced water and salt permeation.

The GEIC’s state-of-the-art testing facilities support industry collaboration, enabling certification and broader adoption. By driving advancements in smart, low-carbon materials, the GEIC contributes to the evolution of sustainable construction and the global journey toward net zero targets.

Zena Holloway - Rootfull

Zena Holloway - Rootfull

Rootfull is pioneering a new paradigm in bio-fabrication by guiding plant root as it grows to create novel materials.

In just 12 days, the wheatgrass seeds sprout and the root grows down onto delicately carved, natural beeswax templates to create different shapes and textures.

Rootfull extends the limits of 3D printing and ushers in a new era of programmable, sustainable design.

ZeoForm - Zeoboards

ZeoForm - Zeoboards

Zeoboards are structural flat panels made entirely from waste plant fibres, bound with Zeoform Micro Pulp (100% cellulose and water).

Aggregates such as hemp hurd, sawdust, and sugarcane bagasse are combined to form strong, versatile boards without glues, resins, or petrochemicals.

Designed for the built environment, Zeoboards can be machined and finished using conventional woodworking tools, but their applications go beyond timber products.

They provide a sustainable alternative to materials such as MDF, stone, marble, and solid wood, making them ideal for feature walls, joinery, cabinetry, furniture, and cladding. At end-of-life, boards can be recycled or biodegraded.