Year in Review 2025: Carbon - How do we tackle it?

Kickstarting our content in 2025 was the topic of carbon, and - specifically - how we might tackle the reduction of it in the built environment.

Across our Studios, lots of you got involved in discussing this theme both on and offline, with 100s of you attending our seminars as guests, and participating in roundtables, sharing your thoughts via interviews and our views pieces, engaging with our bi-weekly editions of The Edit, and contributing to 1000s of social media shares, reactions and comments, discussing the complex topic that is carbon, both embodied and operational.

As we rapidly approach the end of the year, and ahead of us exploring this topic further over the coming 12-months, we’ve pulled together some of the key takeaways from all of the above content, with differences and similarities highlighted across our Studio regions, plus from the practices around the world that took part in our Carbon-12 campaign, as well as some practical tips from the experts we’ve spoken to.

The overarching sentiment across all of the above combines urgency and practicality: tackling the climate crisis now demands that designers move beyond “intent” to measurable reductions in both operational and embodied carbon. To do this, you believe it requires a combination of:

- Better standards and legislation

- Responsible material choices

- Retrofit-first thinking

- Technology-enabled data and workflows.

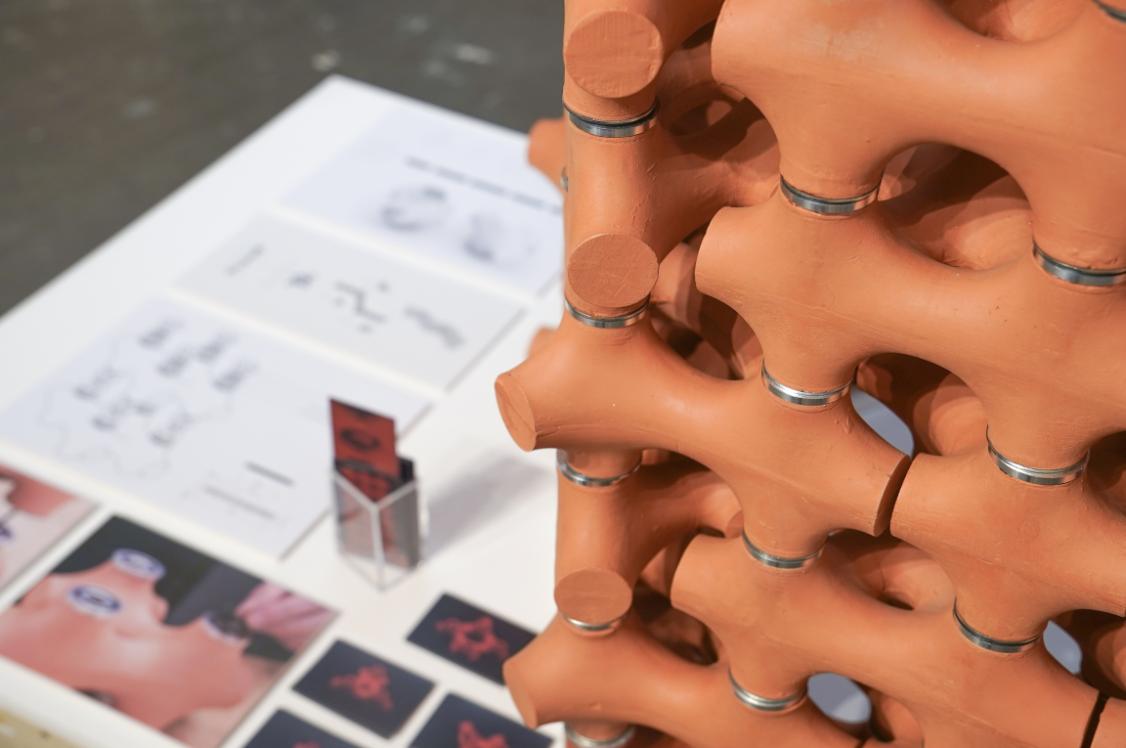

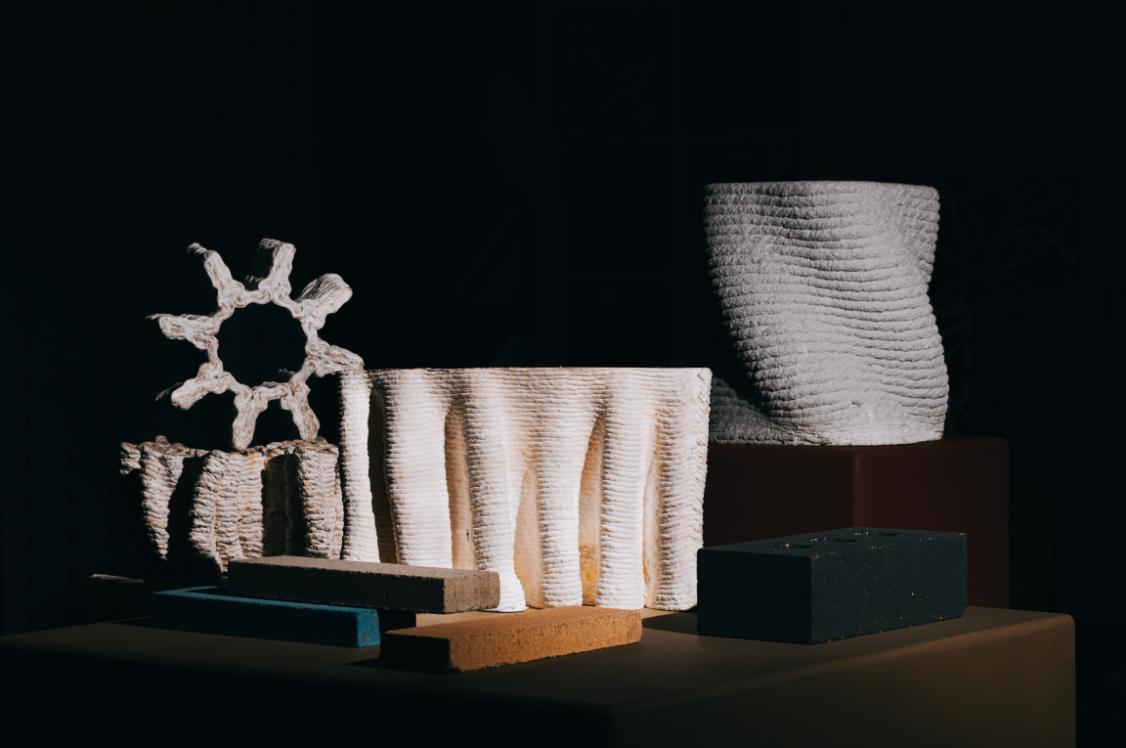

Materiality — the deliberate selection, specification and lifecycle thinking around materials — emerged as one of the most powerful tools to help us reduce whole-life carbon in the built environment.

Top-line overview — what kept coming up?

- Materiality matters: Designers must treat materials as carbon assets/liabilities taking manufacture, transport, use and end-of-life into account.

- Embodied carbon is now front-and-centre: Not just operational energy but upfront embodied emissions - reuse/retrofit are central to meeting Net Zero.

- Standards & incentives: The UK Net Zero Carbon Buildings Standard, and other industry standards, are driving business and regulatory conversations — but implementation, verification and cost remain debated.

- Technology as an enabler: Digital tools (LCA software, BIM-integrated quantification, material databases and generative design) are helping make carbon reduction visible and actionable, though data quality and adoption barriers persist.

- Adopt innovation: Prioritise reuse, repair and refurbishment; new materials/innovations need real-world scaling support to cross the “death valley” between prototype and mass adoption.

Top points raised in the UK

- Policy and standard debates. UK practitioners are intensely discussing the practical achievability of the UK Net Zero Carbon Buildings Standard — cost, scope (operational vs embodied), and enforcement are central concerns. Many practices view a single, coherent standard as useful, but worry it must be realistic and aligned with procurement and finance.

- Material transparency & procurement. UK specifiers are pushing for better EPDs, standardised measuring, and procurement routes that favour low-carbon suppliers. Public sector procurement and corporate client demands are reported as key levers.

- Focus on retrofit. For existing UK stock, retrofit-first approaches are elevated as the most credible near-term route to carbon reductions compared with demolition and rebuild. There was a call for realistic retrofit targets and whole-life assessments.

Top points raised Internationally

- Global practice exchange. International practices (e.g., HOK, Gensler, and Chapman Taylor in the Carbon-12 series) show similar commitments — but different regulatory drivers: EU countries often have stricter disclosure rules and more mature carbon pricing conversations, while some North American markets rely on corporate mandates and client pressure.

- Scale of systems change. The investment in tools is clearly a priority, with open-source/shared databases and design-for-disassembly approaches; they also highlight regionally different material supply chains (timber availability, steel production mixes) that alter design choices.

Similarities between regions

- Shared technical priorities. Everywhere, embodied carbon measurement (LCA), better material transparency (EPDs), and design decisions that reduce waste are top priorities.

- Client and market pressure. Major employers, investors and public tenders are the global levers pushing firms to report and reduce carbon.

- Technology adoption trends. BIM, cloud LCA tools and material libraries are being used widely to operationalise carbon reduction in design workflows.

Differences between regions

- Regulation vs market push. Some regions (parts of Europe) are more rule-driven (mandatory disclosure/targets), whereas others (e.g., parts of US/EMEA) rely more on voluntary corporate commitments and incentives.

- Material supply & manufacturing footprint. Local availability of low-carbon materials (cross-laminated timber, low-carbon concrete, recycled content) varies, shaping feasible strategies.

- Cost and procurement models. Differences in construction cost structures, labour, and procurement norms mean the cost-benefit calculus for retrofit vs new build varies by country.

What should designers consider for their projects in 2026?

- Make embodied carbon part of brief and fees: Ask clients to fund early-stage LCAs (RIBA Stage 1–2) and make embodied targets explicit in briefs and procurement.

- Prioritise reuse & retrofit: Evaluate existing fabric before proposing demolition; quantify whole-life carbon trade-offs.

- Specify for circularity: Choose materials with EPDs, high recycled content, and designs that enable disassembly (mechanical fixings, modularity).

- Use the right tech stack: Integrate BIM with LCA tools and material databases to track decisions and produce auditable carbon reports; invest in training so the team uses these tools effectively.

- Engage suppliers early: Request EPDs and ask manufacturers about decarbonisation plans; support local suppliers where low-carbon options exist.

- Design for resilience and adaptability: Future-proof buildings for changing use to avoid premature retrofit/demolition emissions.

- Advocate for clear standards: Participate in industry consultations and push for a harmonised, practical standard that aligns with procurement cycles and finance.

- Measure, report and iterate: Publish post-occupancy whole-life carbon results where possible; share learnings to accelerate industry progress.

In summary…

Across all of the above, some messages are clear: the technical tools, the conversations and the policy ideas needed to make serious progress exist — but scaling them across procurement, finance and supply chains is the immediate challenge. Designers who seize materiality, embed measurement into early design, favour retrofit and use digital workflows will be best placed to deliver meaningful carbon reductions in 2026 and beyond.

Useful links to more content on carbon

Articles

- How does materiality help us hit Net Zero?

- Net Zero Carbon Buildings Standard: What's the business advantage?

- Is technology aiding sustainability in design?

- Is technology helping shape a more sustainable future?

- UK Net Zero Carbon Buildings Standard: Is it achievable?

- 30 Views: How are we tackling carbon in the built environment?