Is technology helping shape a more sustainable future?

Is technology helping shape a more sustainable future?

This is the question a true constellation of industry superstars were brought together to ponder at Autex Acoustics' new showroom in London.

A great deal of positivity was reflected in the conversation, with agreement that technological tools can enable designers to make better decisions upfront – for example, allowing them to understand what's available to use less material.

Data provides an excuse to go back to clients for post occupancy studies – crucial in ensuring ongoing comfort and wellbeing for end users.

When it comes to data analysis, AI can lead to improved efficiency as it can sift through mounds of information more quickly than a human.

And though concerns have been raised in relation to the sustainability of AI, some members of the group believed it could facilitate regenerative design – with buildings in the future giving more back to the planet than they take. If legislation allows…

As usual, an hour was just enough time to scratch the surface, though a wealth of interesting viewpoints were raised…

Our guests

Naomi Sakamoto, principal, studio director, Gensler

Enrique Soler, design director, Area

Muriel Altunaga Aguirre, founder, The Flow

Dominic Dugan, creative director, Oktra

Sheela Shukla, director, interior design, BDP

Clay Slater Thompson, interior designer, Basha-Franklin

Katie Black, architect, Manalo & White

Jonty Brown, A&D consultant, Autex Acoustics

David Smalley, director, Material Source

Laura Connelly, editor-in-chief, Material Source

A positive influence

To kick off, Material Source Studio director, David Smalley asked the group to consider, “How is technology influencing your approach to sustainable design?”

Naomi Sakamoto, principal, studio director, Gensler, shared that, in the workplace sector in particular, “the challenge has always been embodied carbon.” Though she feels there are some “good solutions in a lot of geographies for in-use carbon”, technology is now supporting architects in making “better decisions up front about the big things that matter”, in terms of the materiality that demonstrates lower embodied carbon for a more holistically ‘sustainable’ building.

Gensler has created its own tool with this in mind, gBlox.C02, for carbon benchmarking to provide fast feedback on products and materials.

“These tools are helping us make the right decisions up front, so that we're not just tweaking around the edges. We're really able to make substantial and influential change at the time when it matters”, Naomi commented.

This technology-enabled analytical approach was also highlighted by Muriel Altunaga Aguirre, founder, The Flow, who referenced the potential for creating inventories for future reuse.

“How do we use less, and reuse and repurpose more? How do we reuse as much as we can in a much more creative way? It’s a combination of a change in mindset, and the adoption of tools to understand what data you have, and what you can achieve.”

Furniture is one area where Muriel believes this is being done to positive affect, sharing a project she’s worked on with a Russell Group University, utilising sensors to “understand where the furniture is, what the level of deterioration is, and, if possible, the brands too.”

Just in the way you have clothes in stock in a retail store, Muriel said by adding the furniture to a BIM (Building Information Modelling) system, you can make informed decisions about reuse and repurpose.

The theme of monitoring was continued by Dominic Dugan, creative director, Oktra, who said, “On the point of strategy, it isn’t necessarily building what you want to build on day one, but building, let's say, two thirds of it, and investing in monitoring. It gives you information, and, providing you’ve got the right client, it can be hugely useful.”

This also applies later down the line at post-occupancy stage, Dominic believes. It can serve as “proof” that either changes need to be made, or that decisions made were correct. “You actually get feedback on how happy people feel in a space – beyond utilisation. People start to ask ‘why?’ about use. It could be as simple as a desk not being used because it’s under an air conditioning unit, for example. But it’s a good excuse to ‘get back in’ to see a client’s space.”

“Are all clients receptive to post-occupancy studies?” David asked.

The feedback was that it’s mostly larger firms that are – and those collaborating with architects longer-term as it informs strategy – “the clients you’re on a proper journey with”, Muriel suggested.

Though there can be a perception that technology only supports with the quantitative side of data capture, Enrique Soler, design director, Area, feels it can benefit the capture of qualitative feedback too. “Now, technology can capture what might have happened at the water cooler. Most of us have used post-occupation surveys at some point, and it ticks a box. But the new generation of surveys are giving a lot of freedom to people. And when the data comes back, it might be completely impossible for a human to sift through and filter it due to the sheer volume – but AI can do it now. Magical.”

A waste reduction model

In addition to the potential for gathering and analysing data, Enrique mentioned AI’s new role in model making helping with the reduction of waste. “I find the most impactful things are usually the most boring to talk about”, he laughed, “but we’re actually saving a lot of material from landfill.”

Plasterboard cut-outs are now said to be a thing of the past, with tools such as Revit. And this has led to greater efficiencies – “your quantities are very, very exact when you are ordering now – reducing waste”, Enrique shared.

As industry disrupting as Revit was when it launched, it now continues to evolve with dedicated plug-ins to calculate Life Cycle Assessments, for example, helping architects to make more sustainable decisions, more easily, than ever before.

At BDP, Sheela Shukla, director, interior design, BDP, shared the team uses Power BI. This creates spreadsheets for QS’s with very clear information on material calculations. Working closely with the in-house sustainability team, Sheela said the practice-developed tools are helping on all levels of workplace design, from furniture and fit-out to the details such as fluid dynamics and daylight studies – parametrics – and how this links to biophilia.

The creation of visual, adaptable models allows conversations with the client. And Sheela commented, “It’s the combination of all these things that’s interesting. And if you think about the amount of time that would take, plus the skill that was required, and now this AI software can produce hundreds of variations so quickly – it’s mindboggling.”

Producing clear material calculations at the start of a project can help make even marginal gains in terms of cutting down on waste, and carbon, Clay Slater Thompson, interior designer, Basha-Franklin similarly believes. And that has to be a good thing.

“What are these material calculations based on?” David asked, referencing EPDs and whether the guests’ practices have their own physical and digital product libraries.

Dominic said at Oktra a software tool is available to shortlist preferable products based on lifecycles.

Sheela added that at BDP, suppliers are called upon to provide product information related to an EPD, and this then creates a shortlist of trusted products and materials based on sustainability criteria.

At Gensler, the practice has recently digitised its whole library to make sure that everything in it is aligned with product specification. “We have global standards”, Naomi shared. “Everything has to meet a baseline standard and then we have a higher level of ambition that we can ratchet up depending on the client's appetite, and their journey.”

The criteria allows searches to be “nuanced” Naomi adds. Whether it’s looking at embodied carbon, recycled content, the social story – “there's a few different lenses that we can look at it through.”

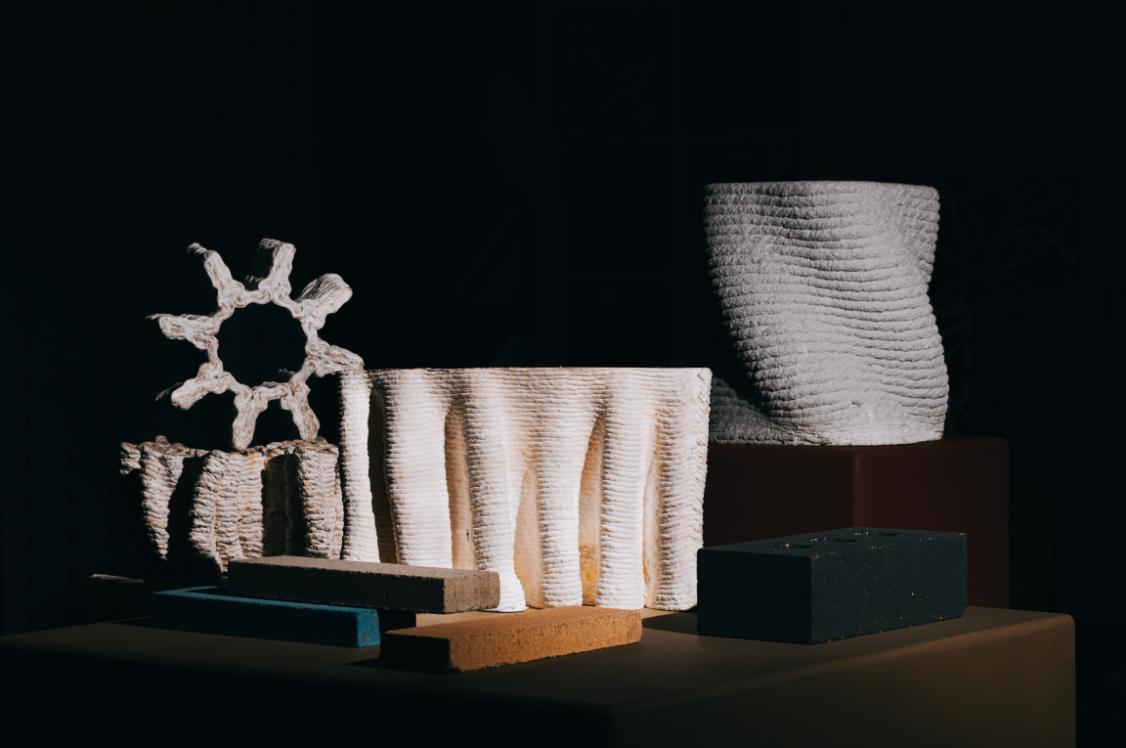

By way of a spectrum, there are also “sunrise and sunset materials”. “There are materials that we don't love using, we know they're not the best, but we just don't have great options. And then we've got the ones that are too early in their maturity to have EPDs. It might be mycelium, it might be something made from avocado skin - we really want to use it, but they don't have EPDs, they're not commercial. But we want to be part of their scaling up.”

This investment in innovation has been reflected in Material Source’s own collaboration with Gensler, lending our biomaterials exhibition for the European HQ teams to support their own research into more sustainable products.

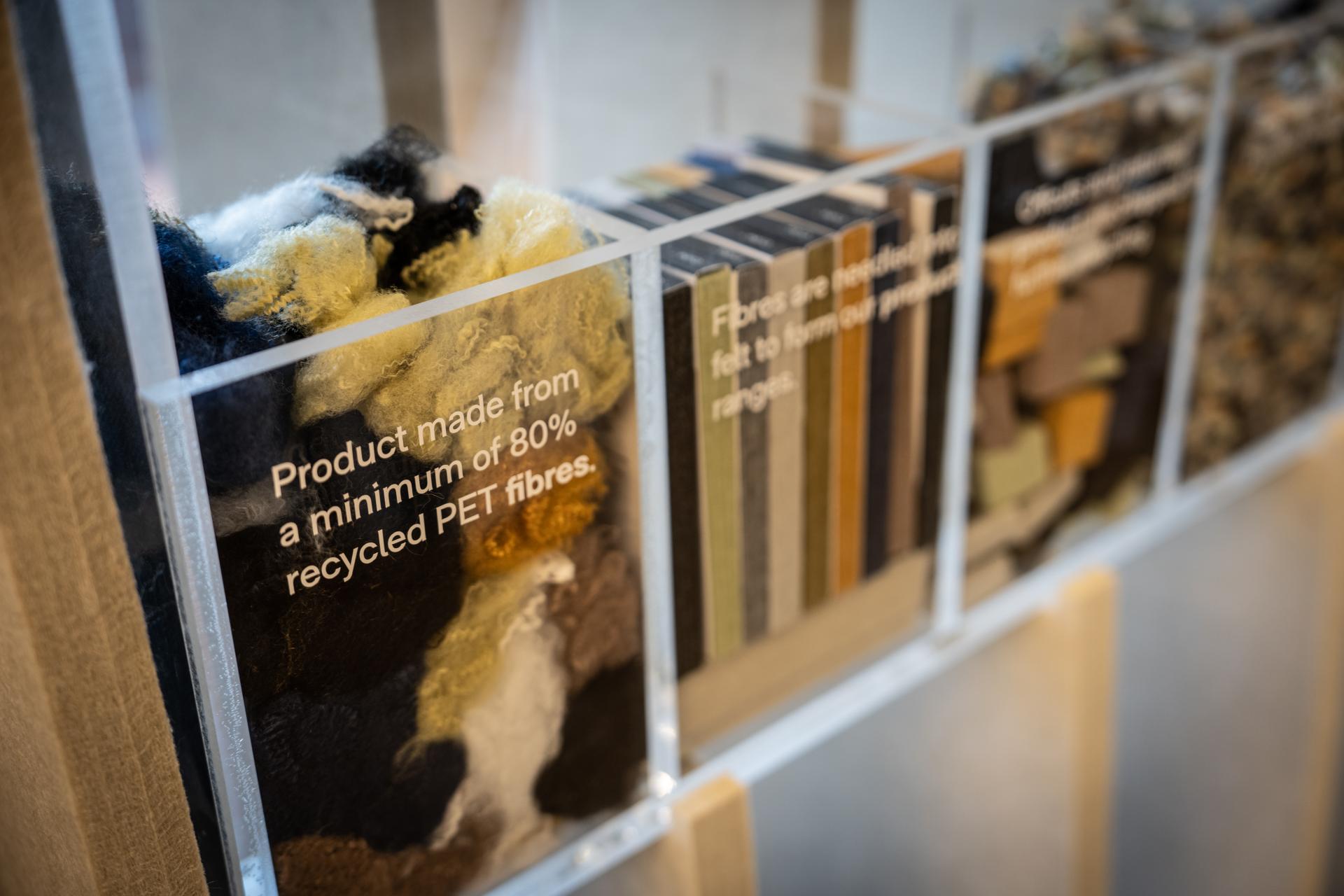

On the topic of sustainable solutions, Jonty Brown, A&D consultant, Autex Acoustics, introduced the group to SpinFix – a RePET mounting clip for acoustic panels made from 100% recycled waste, which eliminates the use of adhesive during the installation process. The benefits of this are plentiful.

“Sustainability is at our core”, Jonty said, “and we’ve recently invested in a palletising machine to divert manufacturing waste offcuts back into the product making process.

“With SpinFix, a client doesn't have to glue our panels, so it's low VOC. It means at the end of life, we can rip them off the walls and we can recycle them, or you can take them to a new lease or a new room or a new office – they become an asset.”

“Who’s driving sustainability”, David asked, “the client or the internal team?”

“For us, it’s led by the client”, Katie Black, architect, Manalo & White said. “And that often comes down to budget, and accreditation”, she continued. The latter of which, she said, can be “bare minimum”, so the inspiration is to build on that.

Going back to basics

In an increasingly digital world, there is an evident movement for people returning to traditional ways of doing things in some cases.

Clay believes this applies to disassembly. Echoing Autex’s approach to simplifying reuse.

“Not using glue everywhere, being more considered with where we put materials, not using screw fixing to join stuff together…working with a good contractor is invaluable – someone who’s got your back.”

When it comes to working with contractors and QS, Enrique – who has a vast amount of experience working in the construction sector – commented, “Though lots of QS out there care deeply about sustainability, we still have to fight the fight. Rather than thinking short term it’s about considering whole lifespans.

“The main thing for me about sustainability is that you don't think about the occupation period of the building. You think about the lifespan of the planet. Then obviously everything changes.

“As you were saying, Jonty, when using recycled PET, it’s great because it’s given multiple lives.”

Proof of concept

Referencing a project pitch at the ‘cheese grater’ as it’s affectionately known in London - The Leadenhall Building – Dominic shared that through the use of technological tools, a proof of concept was created to back up common sense – diverting spend to the areas that really mattered.

“The budget that was developed was assuming that the client would start from scratch – a full delapse of what was in the space. But that stuff was worth a lot of money. The only thing that had changed was time. So, we did two things. We created a model using 3D software showing how those rooms could be maintained in the structure that they were. And we had an acoustician confirm the quality.

“Through modelling, we also got our mechanical sub-contractor to prove that by utilising all the duct work and local fixings it would last the lifecycle of their lease, which was 10 years. And we won the job. Because effectively we saved the client time and money. It’s quite a nice story of how technology can be used for good.”

In addition to modelling, Naomi shared that at Gensler, AI is used to create personas for users who don’t yet exist.

“Imagine you're building a college campus that's going to be open in 20-years. Those people haven't been born yet. Or they're two. And you can't go and talk to them. Or present to them. We use AI generated tools to help develop personas that tell the story to clients. To help them understand, 'Wait, this person cares about sustainability because their life is impacted by climatic events.' And they want to be part of an organisation that’s communicating that they care.”

Divider or equaliser?

“Is technology allowing us to democratise being able to use it for a sustainable end?” David asked the group.

Muriel, who started her own company two-years ago, feels like size matters when it comes to the ability for a practice to develop their own bespoke software versus having to use off the shelf. “Can you imagine, even five-years ago, nothing good was available. But now, there is. So, with time, we’re going towards some kind of democratisation, especially if there's a willingness to share information. I think we are in a sweeter spot now than 10-years ago. There's a lot of shared resources”, she said.

This also applies to the democratisation of sharing information within practice teams, Naomi added. “It used to be that we had sustainability specialists, and we still do. We have people that do LCAs all day. But now, anybody - junior designers coming in - can see in various degrees of detail what the embodied carbon, recyclability, end-of-life strategies are for any material that they specify. And I think that is a technology-enabled change that's happened in the last few years.”

Looking ahead

David asked the guests, “What do you expect for the future?”

Sheela returned to a point made by Muriel at the start of the session on the need to use less.

Though as designers, the best intentions are had, there is always a brief and a budget to take into account, Sheela said. So with this in mind, “we need to try to use less.”

“When we think about biomaterials – mycelium, shells, whatever it may be, it has to be done on an industrial scale to make any difference.

“I remember trying to specify some acoustic material which was made from coconut. And then, of course, I couldn't because it didn't meet the fire requirements for the insurance.

“All of those things are really difficult to get over. So, for me, I think it's just got to be less.”

As was discussed, technology is supporting this. “With more advanced technologies such as large scale 3D printers, you can have tailor-made solutions for specific areas”, Muriel elaborated. “And in the near future, you will be able to produce something round the corner instead of importing it from Australia, for example.”

This point about local sourcing, Clay believes, will “democratise the ability to create sustainable materials.”

Currently, there is an evident gap between innovation and commerciality in some cases, as Sheela pointed out. And it’s not through designers not wanting to embrace better ways of doing things but systemic issues blocking wider adoption. In that way, is securing the democratisation of sustainability entirely possible?

Naomi thinks it’s ambition that’s needed – even more so in the face of adversity. “I would love us as an industry to be more ambitious. If we know that the world is rapidly urbanising, that means more buildings, that means more people living in more buildings. The only way we're going to hit our climate goals is not by doing less harm, but it’s about buildings that actively heal the environment. Regenerative design.

“I think that that's a standard that we as an industry have not stepped up to yet. We've been happy with being less bad”, she added.

As a practice, Gensler is investing in its own research around building integrated carbon capture. “We have fans on every single roof of every single commercial building. We have technology that exists that can filter out germs…the same way we filter out germs, the same way we filter out dust, we can filter out carbon. Then what if we were to use that carbon for something positive?” Naomi posed. “If we think a little bit broader about what a building could be, and use our creativity…”

On the systemic landscape, Muriel queried, “Have you challenged local legislation around the kind of materials you want to use?”

“It’s a journey”, Naomi responded, “Every single jurisdiction is going to be different, and it all comes back to, what's your carbon grid? But I do think that if we're not pushing, who's pushing? If clients aren't pushing, who's pushing?”

As the session drew to a close for now, Katie took the conversation back to the very start – to the topic in discussion, to ask: What is technology? And how does sustainability relate in the first place?

“A lot of technology is powered by something. There's a lot of electricity - or something - involved. And that has a sustainability aspect to it. So how do we make technology run off of something that is positive as well?”, Katie questioned.

“Do we look into renewables and making sure that that is integrated within everything that's done at the other end of the system? Rather than just, ‘We're making this bit work, but everything that's working behind the scenes is still not helping’”, she added.

And globally, what works in one part of the world may not work in another, Muriel commented. “We’re talking about technology as a global thing, and we talk about building as a global thing. But I think that with the ways we build now, we could be much more fine-tuned to the way the climate works. A building here shouldn't be the same as a building in Madrid. And definitely not the same in Nairobi - the climate conditions are different. Yet, we're still building the same things over and over again, everywhere.”

By questioning the way things are done in specific detail, greater sustainability gains can be made, the group agreed.

At Material Source Studio Manchester, an example of this being, David raised, when co-founder and director, Michael Rogan challenged the need for full air conditioning when transforming the Grade II listed building. After a period of testing, it was confirmed that just because that was what was normally done, in this case it wasn’t needed due to the nuances of this specific building.

Dominic concurred from his own experiences of Grade A offices being “labelled as comfort, and that's the expectation” – but in reality, they’re too cold. They’re artificial.

“At the end of the day, it's all about common sense”, Enrique agreed. “We have become our own problem in this part of the world, because we complicate things too much - we got trapped in consumerism.”

Fascinating views drawn from a wealth of experience – we can’t wait to continue this conversation further over the coming months.

In the meantime, a huge thank you to our guests, and to our supporters for this event, Autex Acoustics, Partners at both Material Source Studio Manchester & Glasgow, and with a brand new showroom in London where this session was held.

Have you got something to add? Let us know!

All image credits: Robin Boot