TerraCool harnesses the natural cooling properties of terracotta to curb the increasing temperatures of our cities.

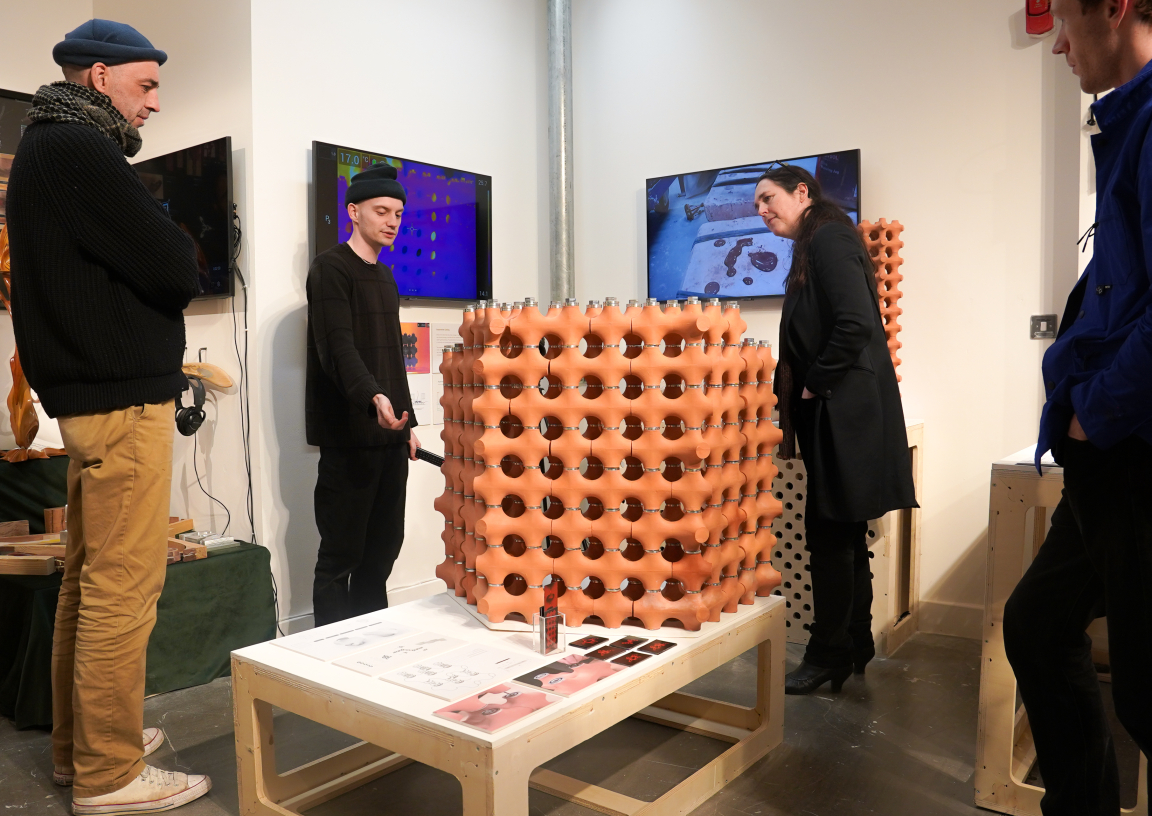

TerraCool is the new innovative solution put forward by Bartlett School of Architecture graduates, Dilara Temel and Lachlan Fahy to address the pressing issue of extreme heat in the built environment.

Extreme heat is impacting our urban environments at an exponential rate, with the metropolis' harbouring warmth in its man-made surfaces. TerraCool is designed to curb the effect of ‘urban heat islands’ - an occurrence of raised and retained temperature when cities replace natural land cover with dense concentrations of pavement, buildings, and other surfaces that absorb heat. Offering a passive cooling system based on Ceramic Evaporative Cooling (CEC), TerraCool harnesses the natural properties of terracotta to create comfortable thermal environments, while reducing energy consumption.

Emerging first from the Bartlett School of Architecture’s Design for Manufacture course in 2022, Dilara and Lachlan have gone on to present their project, TerraCool, at respected design events, such as Dutch Design Week.

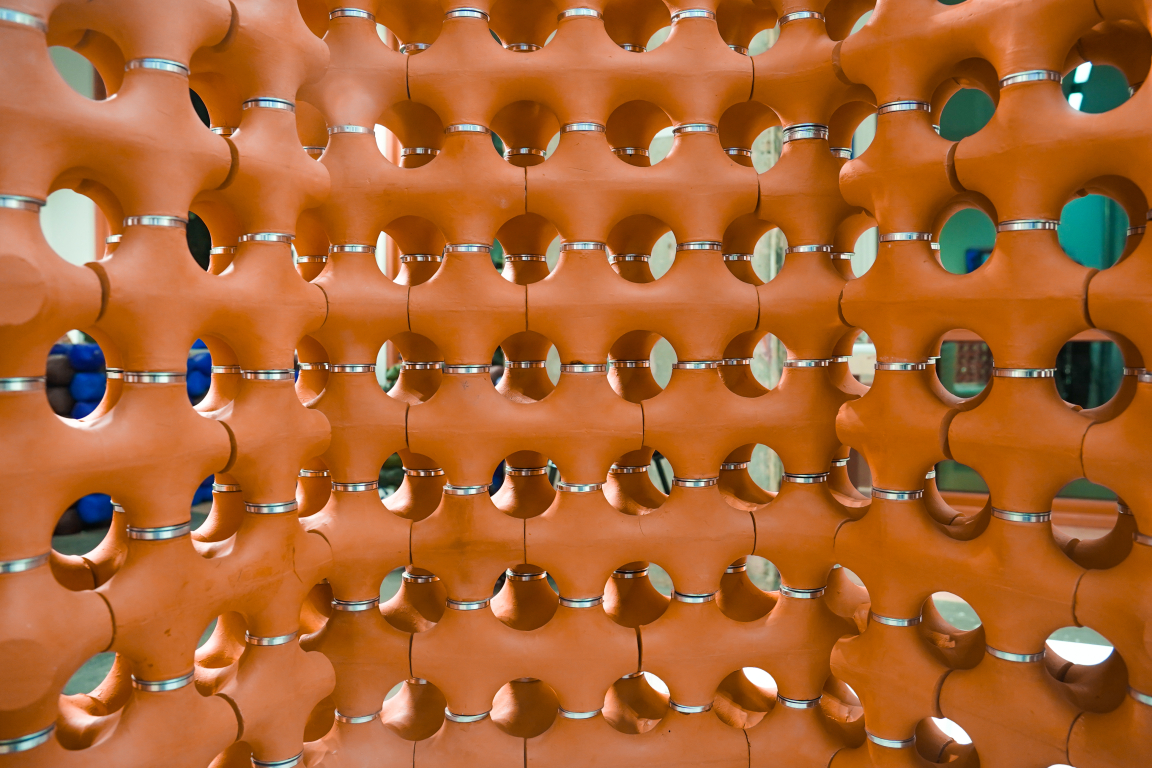

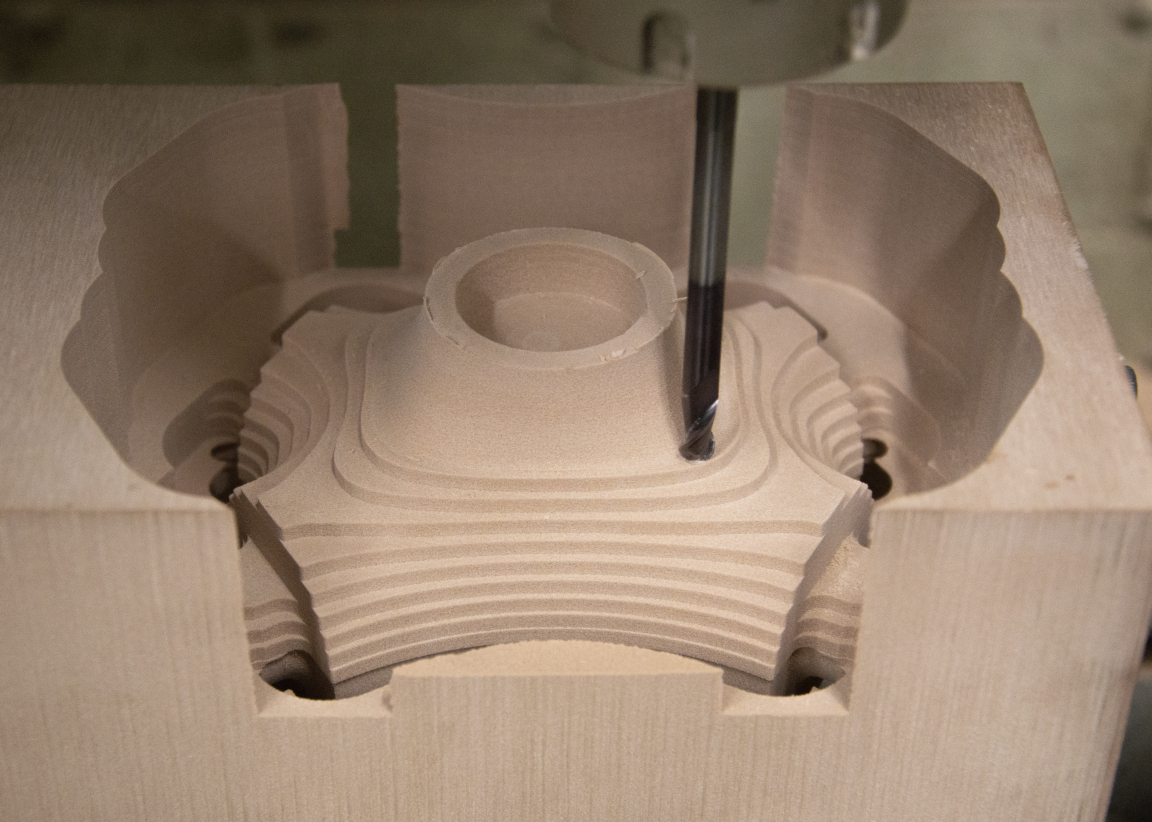

The porosity of fired terracotta allows water to permeate the material, which evaporates on the surface, cooling the ambient air through the phase change of liquid water into vapour. TerraCool's research focuses on minimal surface geometries and parametric design to optimise the surface area for maximum cooling efficiency.

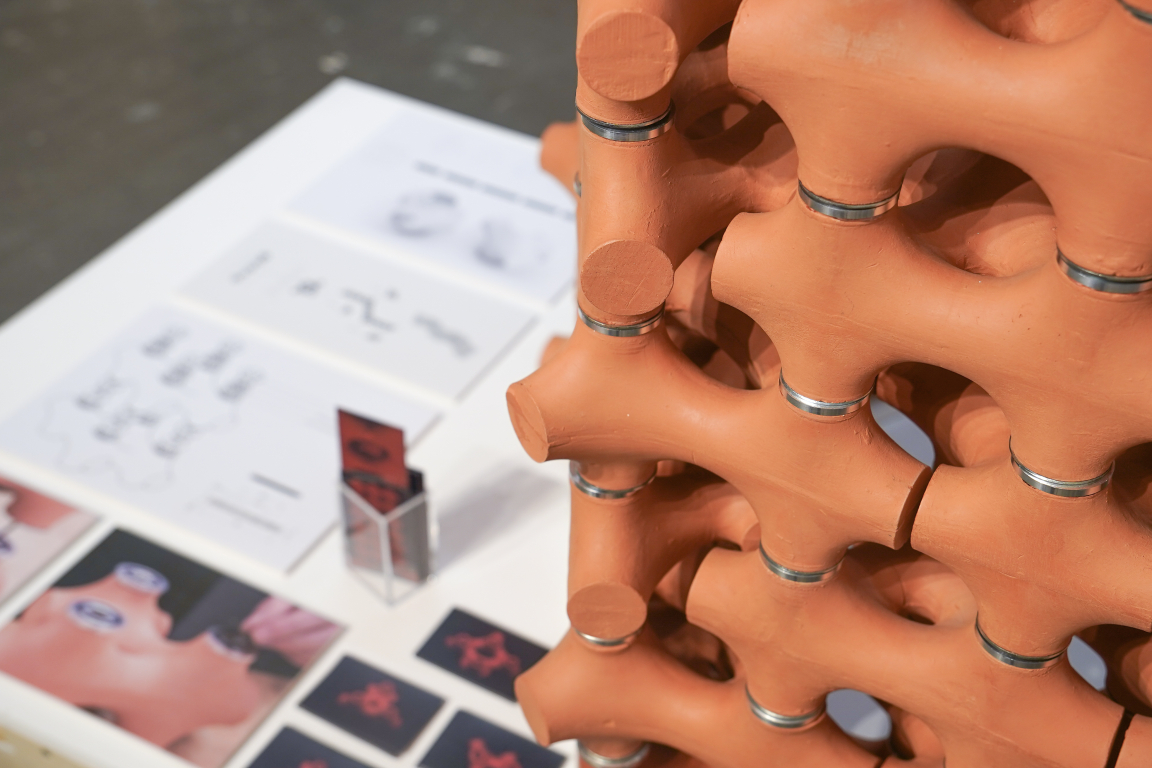

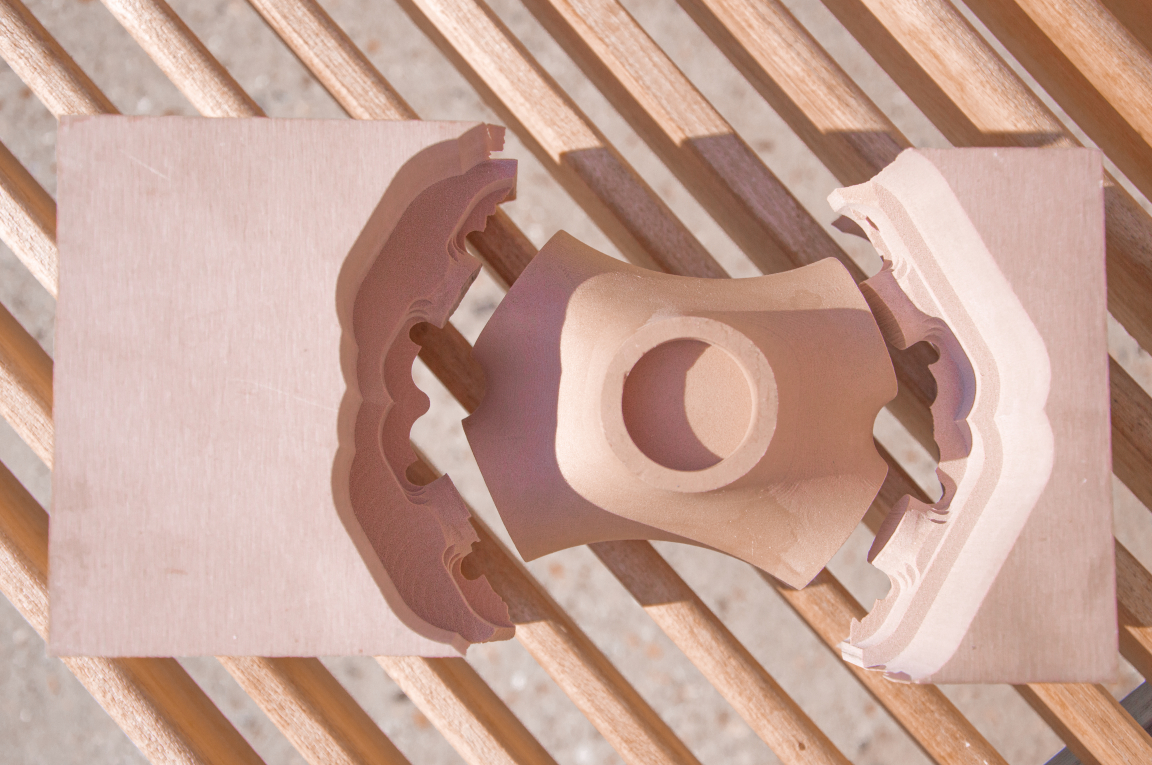

The modular ceramic bricks are cast and then stacked horizontally in a staggered formation, creating aerodynamic gaps for unrestricted ventilation. The hollow geometries of the bricks minimise internal volume, reducing water consumption and structural load, while their curves form a funicular structure capable of withstanding compressive forces.

What sets TerraCool apart is its parametric system, allowing for customisation based on local climatic conditions. Digital and manufacturing parameters can be adjusted to vary the scale, form, volume, and material properties of the bricks, including wall thickness and porosity.

This flexibility enables bespoke units to be developed in the design phase, tailored to the specific requirements of each project catering to the demands of its surrounding environment. The slip-casting manufacturing method used by TerraCool is cost-effective and uses widely available materials, making it accessible and scalable.

TerraCool is a solution that aims to combat the impacts of extreme heat in urban areas and promote the widespread adoption of CEC. This open-source solution employs innovative design, sustainable materials, and customisation based on local conditions, making it a promising approach towards creating comfortable and energy-efficient urban environments.

Its versatility allows for it to be adapted for use both indoors as a ventilation component and outdoors as a cooling screen in public places. The water source of the system has been chosen sustainably, as well as the electricity, taking into account the one significant issue with evaporative cooling systems.