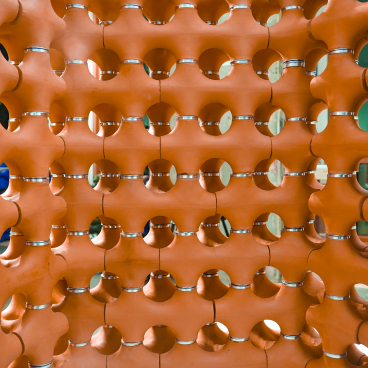

StoneCycling & Circular Matters' CornWall® - a material made from regional organic waste corncob cores otherwise destined for fermentation.

Image courtesy of StoneCycling

You may have spotted CornWall® as number 14 in our This. Is. No. Longer. Speculative. list of 24 bio and by-product-based materials for 2024.

Covering both bases, StoneCycling & Circular Matters' natural alternative to the more harmful fossil-based plastics and resins produced every day is thoroughly a future-facing solution - and one we felt was worth delving into further.

So what is CornWall®? And how is it made? Read on to find out more...

What is CornWall®?

CornWall® is a tile or sheet material made from regional (Western Europe) organic waste (corncob cores) destined for fermentation, burning as biomass or simply to remain on the field.

As the CO2 absorbed by the fibres of the corn cobs during growth is not naturally broken down or burned and thus retained for longer, CornWall® is a CO2-neutral product. There is also no end-of-life waste since the product is 100% biodegradable or can be 100% reused.

CornWall® will be supplied with a demountable anchoring system and is said to be an affordable alternative for ceramic wall cladding or other less sustainable composite materials such as HPL (High-Pressure Laminate). The product is thus not glued and can be removed from the interior if needed - ideal for the flexibility now required in contemporary schemes.

The upcycled product is provided with bio-coating to make it moisture-repellent, and various colours are created by adding pigments. Application includes vertical wall finishing for the interior, such as walls, backsplashes of bars and hotel rooms, and panelling. CornWall® is firm and durable, comparable to HPL and hardwood, but thinner. Dimensions are tight, making it suitable for CNC milling.

Image courtesy of StoneCycling

How is it made?

CornWall® is produced in a sheltered workshop in Antwerp, Belgium. Circular Matters utilises a pressing process to create the products. By heating organic material up to 150 degrees Celsius, the polymers in the biomass activate and form strong bonds, which results in a strong and stable end product. This heating process is electrical, powered by sustainable energy, mainly from solar panels on the roof of the production facility. The production process requires no fossil fuels.

In the future, Circular Matters intends to set up a recycling scheme, enabling the return of end-of-life products. These tiles can then be ground and converted 100% into a new product.

The CornWall® base collection launches with one texture, eight colours and two sizes. Additional high-end textures are said to be following soon. And bespoke options are available for orders over 1000 m².

The CornWall® collection is curated under the creative and strategic direction of Studio Nina van Bart. Studio Nina van Bart is a forward-thinking multidisciplinary design studio that creates colourful, tactile, and high-quality functional designs, specialising in redefining materials for ambitious brands.

Image courtesy of StoneCycling