Anti’s range of lamps repurposes discarded umbrellas destined for landfill.

Anti’s first collection comprises upcycled lamps made of discarded umbrellas, originally destined for landfill.

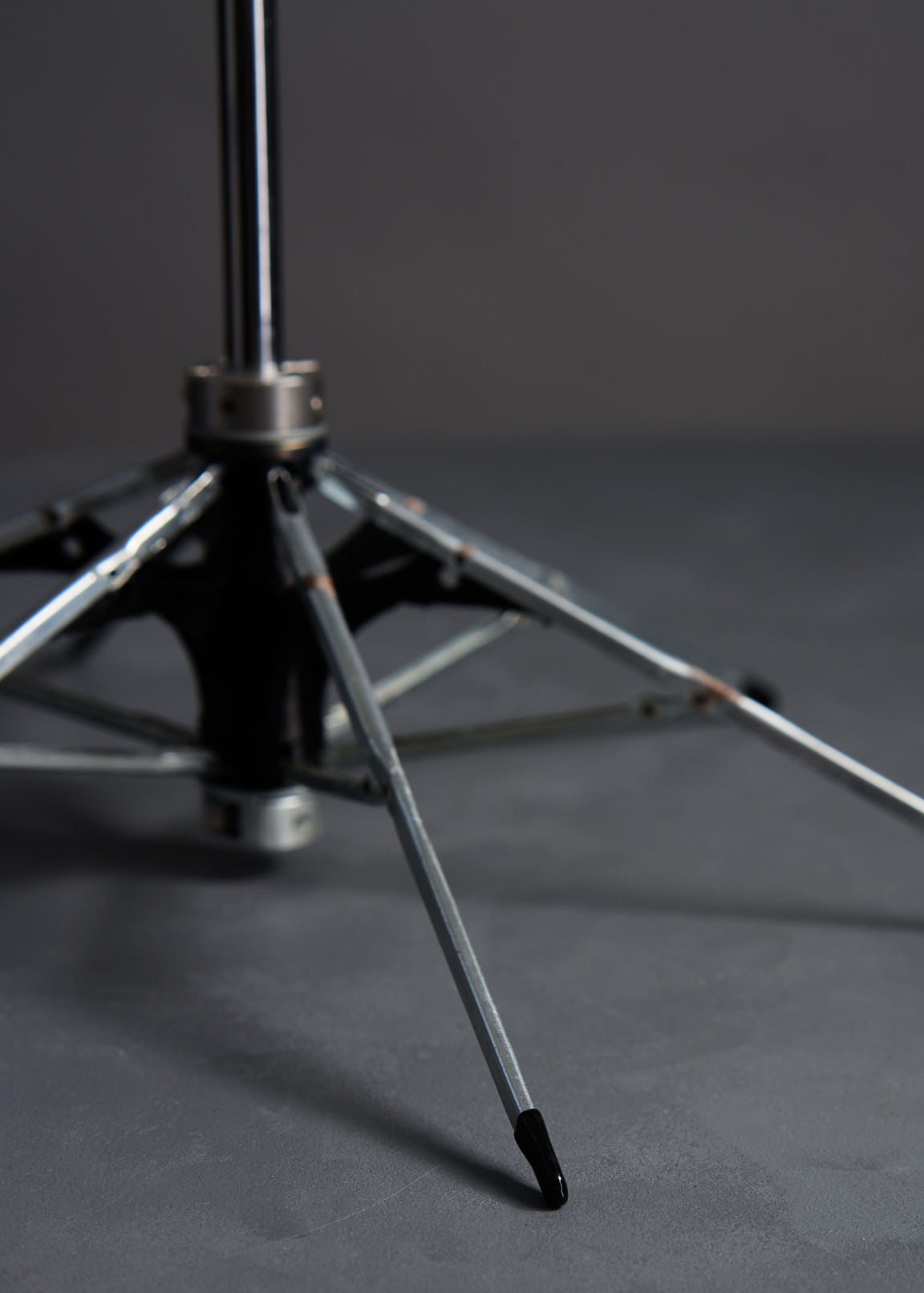

The collected umbrellas are disassembled into their separate materials groups (e.g. plastics, metals, nylon) and are made into desk and table lamps. The new products are deemed easier to disassemble at their end of life than the umbrella was in its original state.

According to the brand, over one billion umbrellas are made each year, but are not designed to last, with an average lifespan of 6 months. The designer addresses a waste issue by "designing with waste, not creating it".

"The umbrella is deemed problematic to recycle due to its complex construction and combination of different material types. A key challenge was making the design repeatable. The design approach has been developed to be capable of replicating the core lamp details whilst allowing for the many variations in umbrella designs."

The designer was keen to retain some of the technical functions of the umbrella. For example, the folding arms have been repurposed into an articulating arm of the lamp, the umbrella plastic runner repurposed into a lampholder and the nylon canopy repurposed into a fabric lampshade for the Table Lamp.

Anti's designer spent three years during the project research phase to understand the umbrella waste problem in detail. He found that ninety eight percent of the world’s umbrellas are made in China, many of which are produced in Songxia - nicknamed ‘umbrella city’.

At their end of life, umbrellas are discarded and often enter landfill or are incinerated. Many are discarded on trains or lost. Research led to discussions with lost property organisations who stated that unclaimed umbrellas are also destined for incineration or landfill. As an example, London Underground's Lost Property department collects ten thousand umbrellas every year.

The designer’s challenge was to give something deemed as cheap and worthless, value and desirability, whilst incorporating C2C values. A big challenge was scalability at the production stage, coupled with an engineering challenge to give something not made to last strength and robustness. The designs needed to compete with existing linear lamp designs, with the umbrella origins being non-obvious at the outset and only becoming apparent on closer scrutiny.